You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Post here for design critique.

- Thread starter Daniel Macina

- Start date

Justin W.

Well-Known Member

If only we could have made the design sooner we would have won and award for sure!me too! i’m gonna call it the “Incog-Zito Assassin Knife”! then i’ll lop two inches off and call it a hunter!

Kevin Zito

KNIFE MAKER

Lol!!!me too! i’m gonna call it the “Incog-Zito Assassin Knife”! then i’ll lop two inches off and call it a hunter!

John Wilson

Well-Known Member

If only we could have made the design sooner we would have won and award for sure!

this thing would win Tactical Knife Over 12 Inches every year!

Ty Adams

KNIFE MAKER

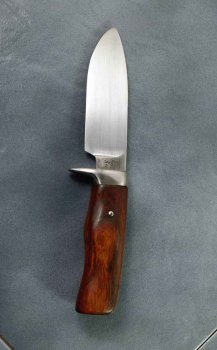

@Kevin Zito pointed out in his design he likes to keep the heel of the knife even with the ricoso. That is a design aspect he tries to keep in his knives. There has to be a good reason for it, and I would love to discuss it. His knife looks great, and obviously needs to be made. Kevin don't wait to long someone will beat you to it. As knife makers a huge challenge we have is making a knife that is functional and beautiful all at the same time.

As knife makers a huge challenge we have is making a knife that is functional and beautiful all at the same time.

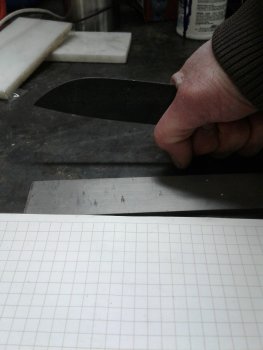

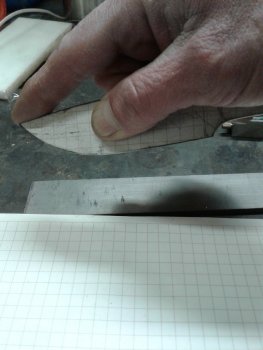

I'm going to talk about how I design a hunting knife, and would like feed back good or bad. Function along with clean lines is something I try to design in each knife.

I try to match the heel of the knife with the belly of the blade. When field dressing game 90% of the work is done from the belly to the tip. I don't want my hand to interfere with any type of cutting work.

On this knife I tried to find a good balance point. Roughly 5/8" above and below the center line.

The knife has to fit well no matter how you hold it. Your palm is longer than your fingers. So the spine is always longer then the belly of the handle. In an introvert grip I want the handle to ride in my palm.

My blades are generally 1" or wider for a pinch grip. I like to have control of the blade in the area that poking things can ruin a hunters day. This also leaves your off hand free to hold a leg, tail, and other floppy things when you're by yourself.

I'm going to talk about how I design a hunting knife, and would like feed back good or bad. Function along with clean lines is something I try to design in each knife.

I try to match the heel of the knife with the belly of the blade. When field dressing game 90% of the work is done from the belly to the tip. I don't want my hand to interfere with any type of cutting work.

On this knife I tried to find a good balance point. Roughly 5/8" above and below the center line.

The knife has to fit well no matter how you hold it. Your palm is longer than your fingers. So the spine is always longer then the belly of the handle. In an introvert grip I want the handle to ride in my palm.

My blades are generally 1" or wider for a pinch grip. I like to have control of the blade in the area that poking things can ruin a hunters day. This also leaves your off hand free to hold a leg, tail, and other floppy things when you're by yourself.

Last edited:

Daniel Macina

Well-Known Member

C Craft

Well-Known Member

C Craft

Well-Known Member

That is the perfect choke up to use when skinning that delicate area with too large a knife, or one that has gotten too gushy! And yes their is such a word!! The words I underline all fit for the meaning!!

gush·y

[ˈɡəSHē]

ADJECTIVE

- excessively effusive.

"her gushy manner"

synonyms:

enthusiastic · ample · profuse · extensive · generous · liberal · lavish · glowing · gushing · gushy · excessive · extravagant · overdone · immoderate · inordinate ·

[more]

You know I don't think there is a perfect length to a knife. A lot depends on what you are doing with the knife and the man/woman handling the blade!

I once watched a fellow skin a deer with what could have passed as a machete! Evidently he had done it before because he made it look easy! I stood there and watched a few minutes and I had to ask, so what is that knife gonna be when it grows up!!!!

Jason Volkert

Well-Known Member

That's some interesting stuff Ty. I like the way you think

Casey Brown

Well-Known Member

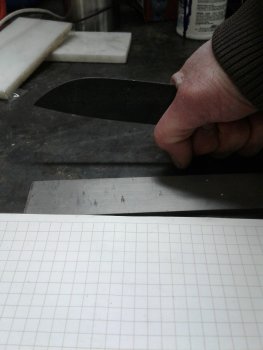

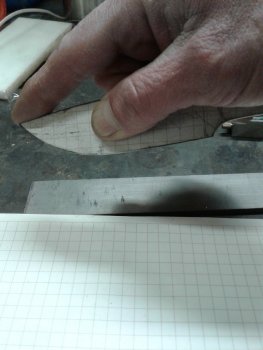

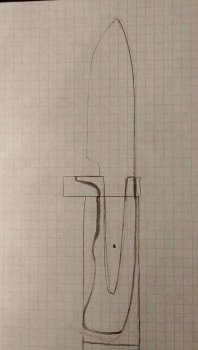

Hey, Ty. Here is something I did when I started doing hidden tangs. Note that I have only done 3, so very much a beginner. However, this really helped me. I designed out the knife sketching in the raw materials also. Then I used my design as a template for everything I did. Then I knew from the start how everything was going to lay up. I would cut out the templates to mark everything up on the block of wood and guard material.This will hopefully be my first hidden tang hunter. The knife it self is larger then I usually make 4-1/4" blade with a 4-5/8" handle. It might be be a little much for my current skill set. I plan to have it finished for the ABS Intro to Bladesmithing class at the end of February. All input is welcome.

View attachment 67024

Casey Brown

Well-Known Member

That's a good idea Casey. I can see myself doing that soon. I think a combination of John Doyle's advice on drawings and what you did will help me design a better knife.

Daniel, I'm glad people advised a narrower tip. I have found a blunt tip frustrating trying to open a belly. I could see the benefit of the blunt tip for reaching in to cut the esophagus and skinning so I didn't comment right away.

Ty, By "choil" are you referring to the space for the users first two fingers? I've got one ground out and noticed the choil on mine is uncomfortable, too. In my case when you turn the knife upside down for gutting. I want to grind it out but it looks like my handle will get too thin. The handle's 5" the blade about 6.5" It's a large knife, but something versatile I have wanted to try to make for moose.

Daniel, I'm glad people advised a narrower tip. I have found a blunt tip frustrating trying to open a belly. I could see the benefit of the blunt tip for reaching in to cut the esophagus and skinning so I didn't comment right away.

The hump for the finger choil might push your fingers back towards the heel some, making the handle feel shorter then it is. Make a template and see how it feels. Some times it looks good on paper but in real life it is uncomfortable.

Here's one I designed had approval from the customer. We were both excited. I made a template, and it was just to uncomfortable in the hand to proceed.

Ty, By "choil" are you referring to the space for the users first two fingers? I've got one ground out and noticed the choil on mine is uncomfortable, too. In my case when you turn the knife upside down for gutting. I want to grind it out but it looks like my handle will get too thin. The handle's 5" the blade about 6.5" It's a large knife, but something versatile I have wanted to try to make for moose.

Attachments

C Craft

Well-Known Member

That's a good idea Casey. I can see myself doing that soon. I think a combination of John Doyle's advice on drawings and what you did will help me design a better knife.

Daniel, I'm glad people advised a narrower tip. I have found a blunt tip frustrating trying to open a belly. I could see the benefit of the blunt tip for reaching in to cut the esophagus and skinning so I didn't comment right away.

Ty, By "choil" are you referring to the space for the users first two fingers? I've got one ground out and noticed the choil on mine is uncomfortable, too. In my case when you turn the knife upside down for gutting. I want to grind it out but it looks like my handle will get too thin. The handle's 5" the blade about 6.5" It's a large knife, but something versatile I have wanted to try to make for moose.

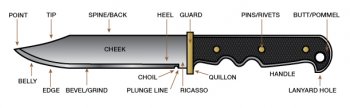

The choil is the funny little hole in the blade edge, just before the ricasso! refer to this

In your picture it would be where someone re-drew the edge and the upsidesoU

C Craft

Well-Known Member

Casey this knife reminds me of a Randall knife!! Take a look at this site and you will see what I am speaking of!! https://www.randallknives.com/catalog-models/ The older works actually done by him are slightly different but similar to your knife!! Two thumbs up on this one!!

Ty Adams

KNIFE MAKER

That was the spot I was referring to. Instead of taking the hump out maybe you could move it forward, down? Round the point out some and see how it feels.That's a good idea Casey. I can see myself doing that soon. I think a combination of John Doyle's advice on drawings and what you did will help me design a better knife.

Daniel, I'm glad people advised a narrower tip. I have found a blunt tip frustrating trying to open a belly. I could see the benefit of the blunt tip for reaching in to cut the esophagus and skinning so I didn't comment right away.

Ty, By "choil" are you referring to the space for the users first two fingers? I've got one ground out and noticed the choil on mine is uncomfortable, too. In my case when you turn the knife upside down for gutting. I want to grind it out but it looks like my handle will get too thin. The handle's 5" the blade about 6.5" It's a large knife, but something versatile I have wanted to try to make for moose.

Andre Grobler

Well-Known Member

Justin Presson

Well-Known Member

I'm home with a sick boy today. He is asleep so spent a little time working on this camp/ranch bowie. I drew it up the other day but it needed some tweaks and I ran off the paper.This one I am going to make for me. Handle will be desert ironwood not sure what the steel will be yet.

opaul

Well-Known Member

I really like that Justin. How thick is it going to be at the spine? How are you going to mill in the fuller? You need to sand out those grind marks near the plunge lineI'm home with a sick boy today. He is asleep so spent a little time working on this camp/ranch bowie. I drew it up the other day but it needed some tweaks and I ran off the paper.This one I am going to make for me. Handle will be desert ironwood not sure what the steel will be yet.

Justin Presson

Well-Known Member

Probably 3/16" thick. I'm not sure on the fuller, last design I drew it ground in with like a 2" wheel. This one would be like a 1/4" round end mill. I have a friend JPSworks who lives about 40 minutes from me that has a milling machine so I may go that route.I really like that Justin. How thick is it going to be at the spine? How are you going to mill in the fuller? You need to sand out those grind marks near the plunge line!