I use a pneumatic Zip Gun with the inlet pressure reduced to around 40-60 PSI. This tool will beat the holly hell out of a chunk of metal. Controlling inlet air pressure is the trick to making the proper texture.

The tip is ground to around 1/8" diameter. Different tip diameters / shapes provide variations in the texture.

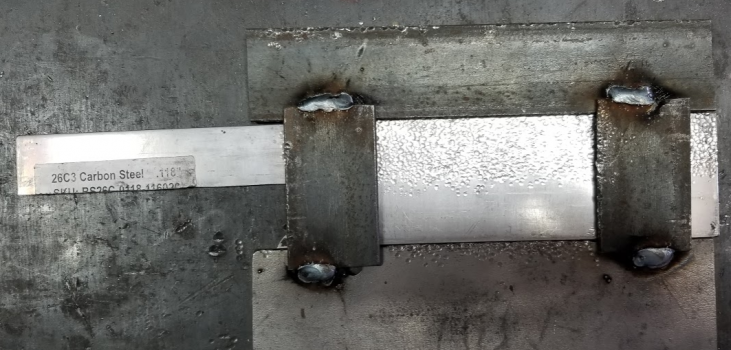

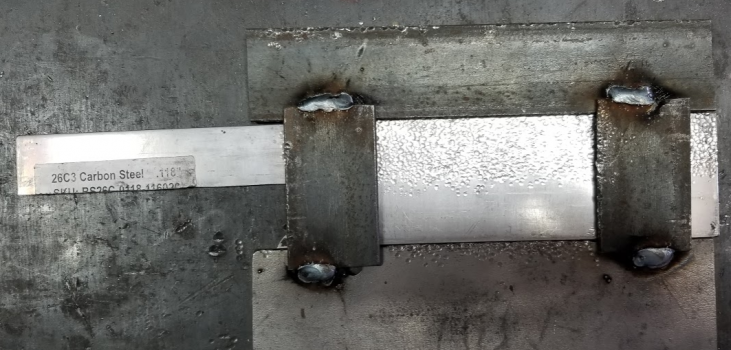

Trying to pound texture into a blank on a bench is difficult since the knife jumps all over. So I scabbed together a cheesy holder for various size blanks and clamp it to my metal base.

This is an example of the results

While the final texturing is appealing, there some things to consider. First, pounding steel in a cold condition distresses the surface and work hardens it. To relieve that stress it's probably a good idea to normalize the blade before HT. But, since the stresses are on the opposite side of the blade edge, I haven't found this to be a problem. I would definitely normalize a long blade.

This surfacing technique will also result in lateral distortion of the blade if the amount of pounded / upset metal is not equal on both sides. That is an issue that needs to be fixed either by uniform pounding on both sides or during the tempering process. Again, I've not found this to be a problem.

I've used this Zip Gun for several decades for all kinds of projects. It's a workhorse, originally intended for cutting / removing sheet metal, and exhaust pipes. The cutting tip makes short work of old rusty exhaust pipes.