scherf68

Well-Known Member

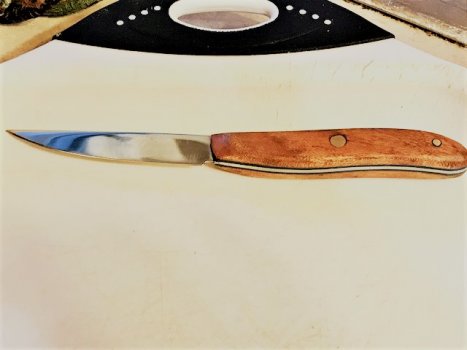

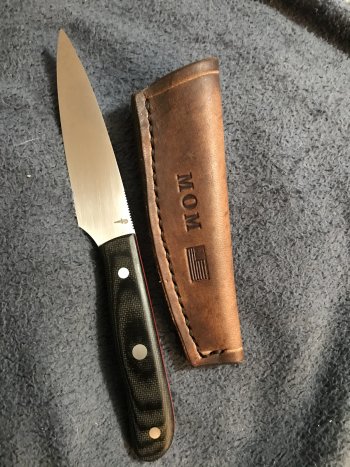

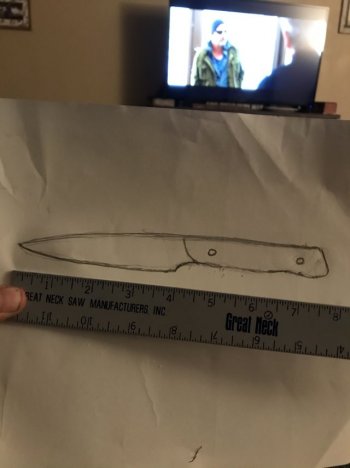

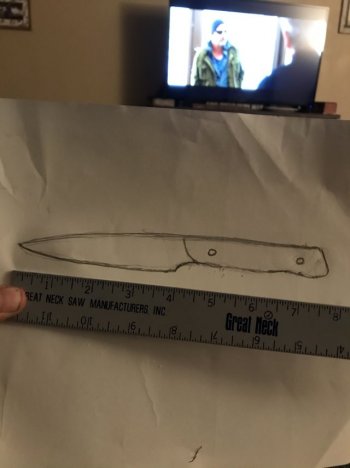

My mother wants me to make a paring knife, have not done one yet. Does anyone have good plans that I could copy, searched google and different shapes and sizes all over the place. I was thinking it would be small, to cut or dice small fruits. My order of AEB-L at .62 thickness arrived and ready to conquer this. How long overall should it be? I just sketched this one out, will it work?

Last edited: