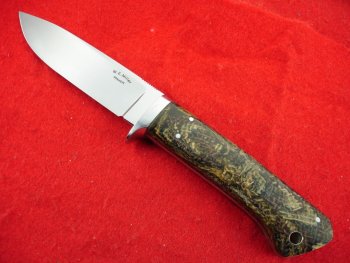

Forged from a round bar of 52100 or 5160 with stabilized maple burl for handle material. The round hidden tang is pinned and epoxied. Flats and shoulders are left as is from forging, blades hollow ground on 10" wheel, back grind the top of the blade to reduce a bit more weight and make easier for penetration. After the knives are completed and sharpened, the handle is taped with electrical tape and the metal is sand blasted. After that, a coat of tool black is applies, oiled down good and resharpened on hard Arkansas stone.

Wood to metal contact is restricted to the small area of the ricasso to retard any moisture to the steel and no bump from shrinking and swelling. There is little of this by using the stabilized wood.

For those that would like to learn this method of making the integral, I will be a demonstrator at Batson's this coming spring on how I do it. I will go from start to finish with a hand out. Kind of like Martha Steward when she cooks, I will have part of it already in the oven to save time.

For those that have never attended Batson's Bladesmith Symposium, it is in my opinion, the best hammer in you could ever attend. Starts on Friday and ends on Sunday at noon. He also has a knife show for a little while on Saturday after lunch that is attended pretty heavily by the public.

Gosh, I guess I could talk a long time when I get started. Sorry about that.