LesterTroll

Active Member

So after my favorite lock back work knife broke due to misuse by me. I decided to take it all apart and fix it. I did and I also realized that it was cheaply made. This gave me all kinds of ideas and the lurking and web searching began. I also realized I had most tools nessessary to build a knife of my own.... just needed some knife steel which I quickly ordered.

This thread may be a work in progress by a newbee.... helpful to some and entertaining to others..... lol. I’m aiming for a slip joint, if you’ve got some know how to share please don’t hesitate with constructive critisism.

Here is where I am as of this evening:

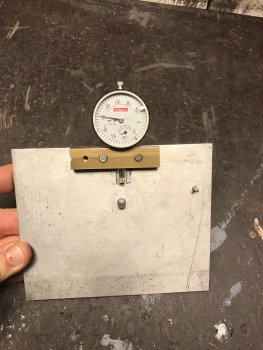

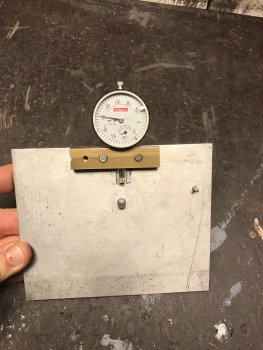

Out of some scraps from the bin:

And the blade and spring.... both 1095

I am having alot of fun !!

This thread may be a work in progress by a newbee.... helpful to some and entertaining to others..... lol. I’m aiming for a slip joint, if you’ve got some know how to share please don’t hesitate with constructive critisism.

Here is where I am as of this evening:

Out of some scraps from the bin:

And the blade and spring.... both 1095

I am having alot of fun !!

Last edited: