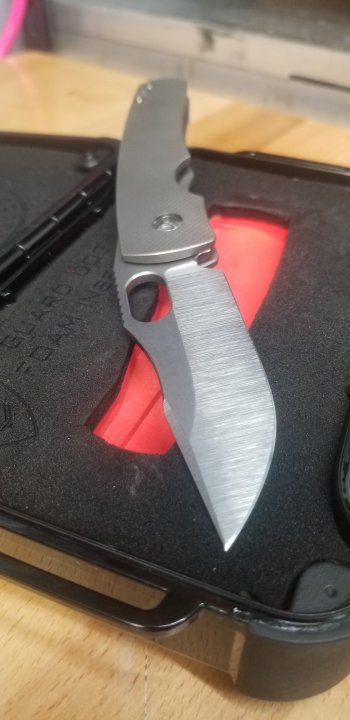

Stang Bladeworks

KNIFE MAKER

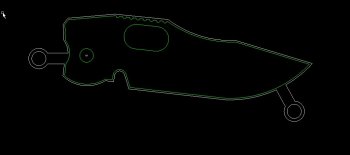

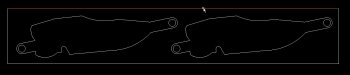

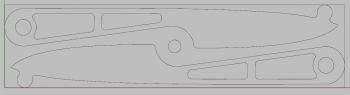

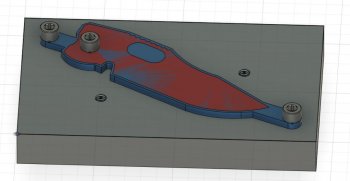

I have been making framelocks for a little while using a manual benchtop mill. This has been great to learn on and I don't regret starting that way. That being said I have quickly learned that it isn't overly efficient. So much of my time is eaten up with manual machining setups that I dont have as much time to focus on trying new things as I would like. In an effort to free up some time and increase my output I have decided to purchase a small cnc mill.

In preparation for this I have been doing online training and researching as much as possible over the last 6 months to help with the steep learning curve. I have examined every machine that was even remotely in my budget and met my requirements. A lot of the more serious machinist recommended either haas or a used machine. The used machine was a little too intimidating for me at this stage. I did meet with haas several months ago but ultimately it landed outside my budget when equipped with the options I think I need. I have decided to go the tormach route. I contacted every knifemaker I knew of who had one to get their opinion of the machines for a knifemaking application. Almost all of them had positive feedback with the understanding that its not a heavy industrial grade machine and it will need to be programmed as such.

I am confident the machine will be capable of what I want it to do and even though its not a large VMC it will be way faster than me on my small mill. I noticed the CNC sub forum here and I figured I would ask some questions here and post what I learn as I progress. Hopefully it can help someone down the road.

In preparation for this I have been doing online training and researching as much as possible over the last 6 months to help with the steep learning curve. I have examined every machine that was even remotely in my budget and met my requirements. A lot of the more serious machinist recommended either haas or a used machine. The used machine was a little too intimidating for me at this stage. I did meet with haas several months ago but ultimately it landed outside my budget when equipped with the options I think I need. I have decided to go the tormach route. I contacted every knifemaker I knew of who had one to get their opinion of the machines for a knifemaking application. Almost all of them had positive feedback with the understanding that its not a heavy industrial grade machine and it will need to be programmed as such.

I am confident the machine will be capable of what I want it to do and even though its not a large VMC it will be way faster than me on my small mill. I noticed the CNC sub forum here and I figured I would ask some questions here and post what I learn as I progress. Hopefully it can help someone down the road.