M

Mook

Guest

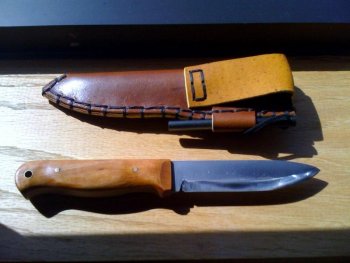

O-1 tool steel, shaped by hand with an inexpensive angle grinder and belt sander, heat treated in a Weber grill and tempered in the kitchen oven.

The handle is from a cherry tree that blew down in my yard 12 years ago. I finished it with one coat of tung oil to deepen the color, and three *very* light coats of oil-based polyurethane.

The sheath is from leather that I bought from the "belt lady" at the flea market. For $20, I got a huge roll of leather cutoffs, more than I think I'll use up in a year. An inexpensive leather punch from the craft store, some waxed thread and some time getting the fit right, and there you go.

The firesteel is one of Ron Fontaine's. The spine of the blade will scrape off a nice shower of sparks. There's a little sooty residue left on the blade afterward, but that wipes off with a t-shirt.

If there are those of you out there, looking at knives like this thinking it takes a mechanical engineering degree and/or thousands of dollars in equipment to make a knife, I can tell you it doesn't. Now, if I were doing this professionally and speed of production were important, I'd definitely want to upgrade some of my equipment. But for less than $100, I have this, the final product. (Now, time spent, that's another issue )

)

And I've already ordered more steel so I can make more of these. A friend of mine likes this blade so much he gave me some curly maple for use on the next knife!

The handle is from a cherry tree that blew down in my yard 12 years ago. I finished it with one coat of tung oil to deepen the color, and three *very* light coats of oil-based polyurethane.

The sheath is from leather that I bought from the "belt lady" at the flea market. For $20, I got a huge roll of leather cutoffs, more than I think I'll use up in a year. An inexpensive leather punch from the craft store, some waxed thread and some time getting the fit right, and there you go.

The firesteel is one of Ron Fontaine's. The spine of the blade will scrape off a nice shower of sparks. There's a little sooty residue left on the blade afterward, but that wipes off with a t-shirt.

If there are those of you out there, looking at knives like this thinking it takes a mechanical engineering degree and/or thousands of dollars in equipment to make a knife, I can tell you it doesn't. Now, if I were doing this professionally and speed of production were important, I'd definitely want to upgrade some of my equipment. But for less than $100, I have this, the final product. (Now, time spent, that's another issue

And I've already ordered more steel so I can make more of these. A friend of mine likes this blade so much he gave me some curly maple for use on the next knife!