You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Morland Picture Gallery

- Thread starter Dennis Morland

- Start date

Don Robinson

Well-Known Member

I like that handle, Demo.

Dennis Morland

KNIFE MAKER

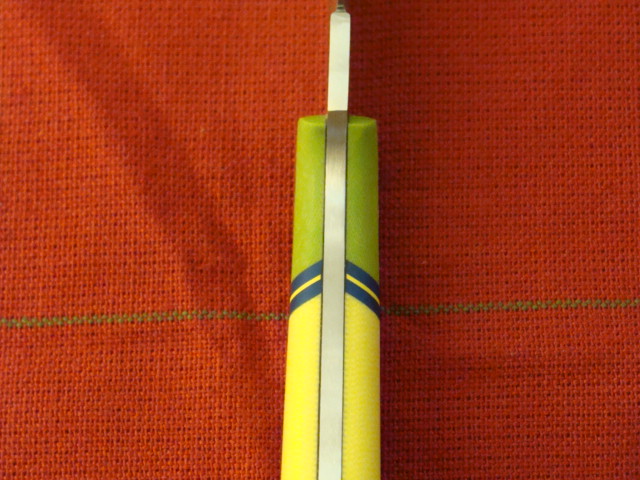

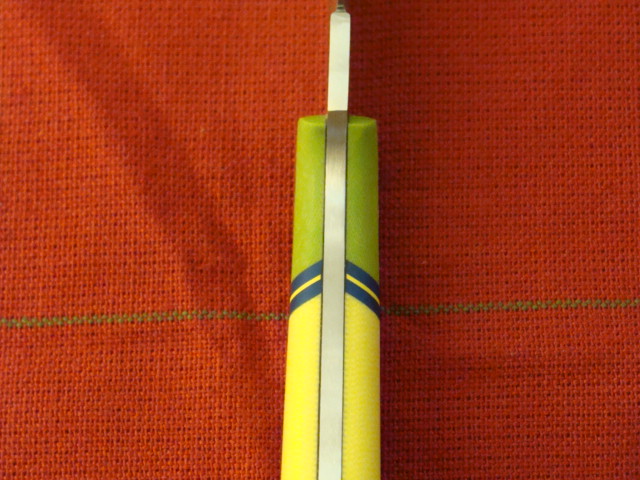

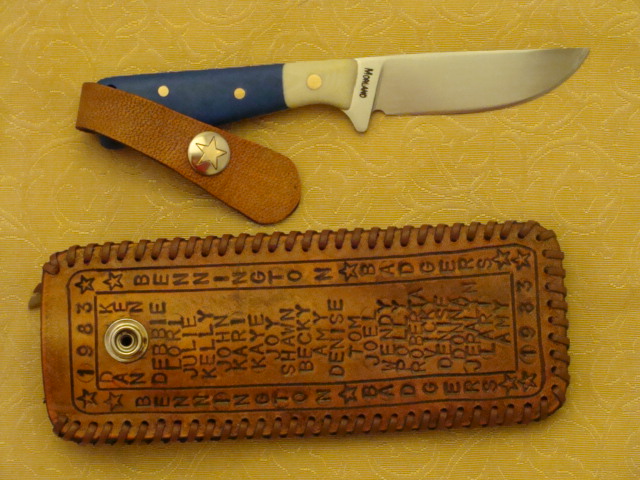

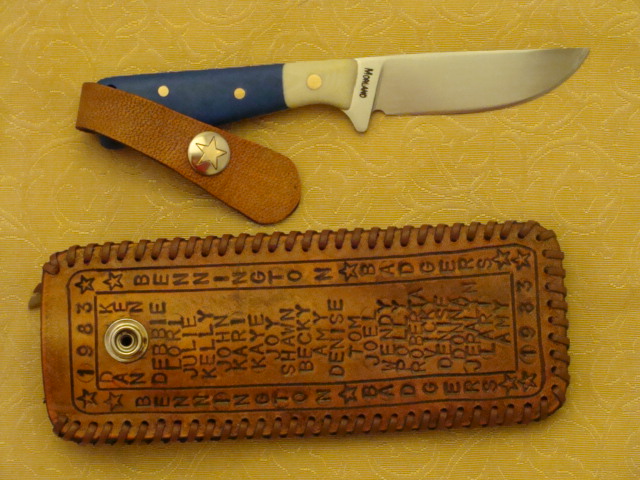

I had a rare few days at home. My son had his nose surgery and someone needed to stick around and take care of him. Lucky me! I got four (4) knives completed. Yippee!! For some makers, that isn't very many. For me, it is a lot. First up, a knife that I made for my 35th High School class reunion. I ended up giving it to a classmate that is recovering from West Niles virus. I do not ever want to get that disease. A little neck knife from 1075 in the school colors and every graduates name on the sheath. It went over pretty well...

Go Badgers!!

Go Badgers!!

Dennis Morland

KNIFE MAKER

Next I had a three finger skinner made from 1095. I had two short pieces and could not decide what to make from them. I came up with these as they are around 6 inches long. I just hate to have shorts and have them go to waste. First one is G10. Black bolsters and trio for scales. Black sheath from Wickett and Craig leather. I really like this one.

Dennis Morland

KNIFE MAKER

Another three finger skinner made from 1095. Again, around 6 inches long made from a leftover short piece of steel. This time it is dyed California buckeye burl. I got the burl from John Doyle in a bargain box. I had a buddy of mine stabilize and dye it. He is just starting to get into the stabilization. He ended buying the knife to show all his potential customers his product. Works for me. Notice, this is my first attempt at a plungeless type knife. I think it turned out well. I'm looking forward to trying it on a much larger kitchen knife.

Dennis Morland

KNIFE MAKER

Last one is another neck knife. Made from 1075. Black G10 scales with a Gold G10 liner. Official colors of the US Army and the Pittsburgh Steelers. This one is going to a friend of mine that is a veteran. May God bless each and every one of them!

Dennis Morland

KNIFE MAKER

That is it for today. Whew! I have several more knives that are nearing completion and should post a few more, soon. Enjoy and keep grinding.

Smallshop

KNIFE MAKER

A Mini-Skinner!Next I had a three finger skinner made from 1095. I had two short pieces and could not decide what to make from them. I came up with these as they are around 6 inches long. I just hate to have shorts and have them go to waste. First one is G10. Black bolsters and trio for scales. Black sheath from Wickett and Craig leather. I really like this one.

Gene Kimmi

KNIFE MAKER

Very nice knives, Dennis. I love those skinners!

Dennis Morland

KNIFE MAKER

Very nice knives, Dennis. I love those skinners!

Thank you Gene. Tomorrow, I get to give away the black neck knife to a US Veteran. Looking forward to doing that.

Dennis Morland

KNIFE MAKER

I have been working on this next knife for about six months. Do a little work, think about it, do a little work, think about it. I have finally finished it up. A buddy of mine helped to design this knife for himself. He is stoked about it being finished. I hope he likes his new mini-cleaver. Made from high carbon steel, copper liners, copper pins, copper inserts, ironwood, a nice hamon, lots of filing, and some Wickett & Craig leather. Pictures are better than words. Just take a look at this beauty.

Last edited:

Kevin Zito

KNIFE MAKER

Dude! These all are amazing!!!!

Dennis Morland

KNIFE MAKER

Here is the latest creation. 1095 and right at 10 inches in length. Black G10 bolster, maple burl scales, copper pins, Wickett & Craig leather.

Pictures are better than words.

Pictures are better than words.

Dennis Morland

KNIFE MAKER

This one is a little different for me. It is a "cheese" knife for my kids' piano teacher. She and her husband entertain a bit and love their wine. Which is better "wine" or "cheese"? Should be a great conversation piece in the kitchen. Made from 440C and G10. Right at 9 inches long. 4.75 for the handle and 4.25 for the blade. Watch out Mr. Swiss... The box is oak with antique brass hinges and corners. Leather inlays and ceramic magnets to hold it closed.