GMelton

Member

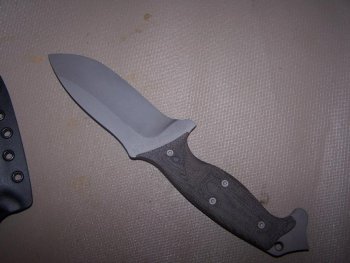

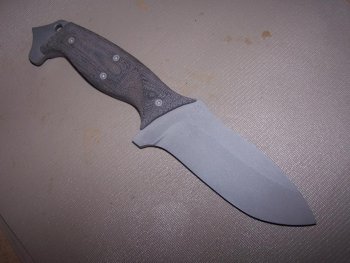

I promised a few folks I would throw up some pics of my next WIP so here we go. This is the Melton Knife and Design, Bravo Smash. It's my most popular Combat/Hard Use knife. Several firsts on this particular knife and project. This is the first knife I have done in S35VN (3/16") so I am excited about that and to see how hard it is to work with. Also this is the first of several knives I just had water-jet. Overall I am pretty happy how the water jet came out.. gonna have to make some adjustments on a couple designs but this one came out well. I had to clean up the edges and do some slight profile work. In this pic we have the blank cleaned up and flat ground.

Here I am using the Dykem Steel Blue so I can scribe two lines for the edge. I usually shoot for an edge thickness of about 1/16" or 50/1000's prior to H/T(heat treat). Any thinner and we'll have issues during H/T.

I tried to get a good pic of the edge. I apologize that I apparently am photo-retardant....Here I have ground to just the outside edge the scribed lines.

I then start a double hollow grind with an 60 grit belt with which I do about 80% of the needed grinding then switch to an 80 grit then finally a 120 which is the highest I will go prior to heat treat. I plan on bead blasting this knife so after H/T I will take it up to a 220 finish then blast it. Taking it to 220 ensures no grind lines with show through the bead blast finish.

I will try to work on the handle tomorrow. Any questions or comments feel free to post! Enjoy!!!

Check out some of my other knves at http://meltonknifeanddesign.com

Here I am using the Dykem Steel Blue so I can scribe two lines for the edge. I usually shoot for an edge thickness of about 1/16" or 50/1000's prior to H/T(heat treat). Any thinner and we'll have issues during H/T.

I tried to get a good pic of the edge. I apologize that I apparently am photo-retardant....Here I have ground to just the outside edge the scribed lines.

I then start a double hollow grind with an 60 grit belt with which I do about 80% of the needed grinding then switch to an 80 grit then finally a 120 which is the highest I will go prior to heat treat. I plan on bead blasting this knife so after H/T I will take it up to a 220 finish then blast it. Taking it to 220 ensures no grind lines with show through the bead blast finish.

I will try to work on the handle tomorrow. Any questions or comments feel free to post! Enjoy!!!

Check out some of my other knves at http://meltonknifeanddesign.com

Last edited: