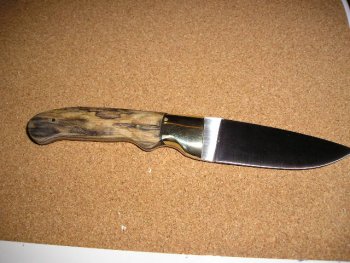

Here is my submission. As I reported earlier, this is a standby, not my first choice...kept having problems with the scales lifting for some reason and I didn't want to send it out hoping it would be ok, if I'm not 100% sure it's not going to fail, it doesn't leave my hands.

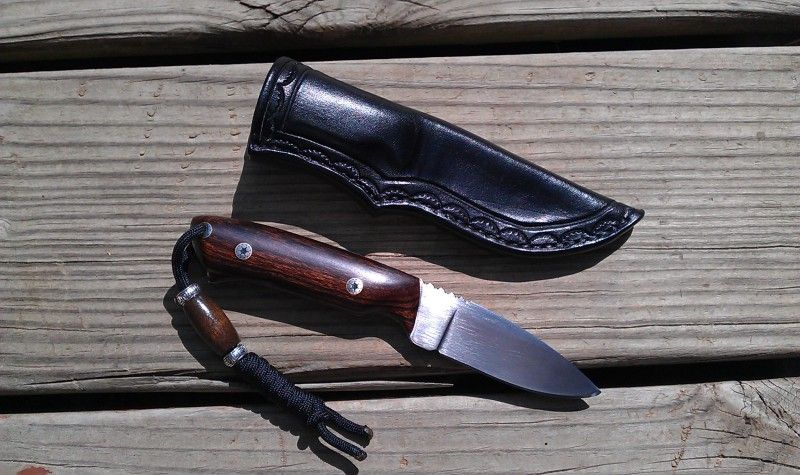

The blade is a drop point skinner in AUS-8 with cryo tempering, hand pulled "brushed" finish, jimping done with a carbide cutter. Handle is Arizona Desert Ironwood, finished to 2000g and waxed, with matching brass and stainless mosaic pins and a matching mosaic thong tube. Lanyard is black paracord, Chris Reeve style knot, 2 metal beads and 1 wood bead. The sheath is 8/9oz veg-tan, basic pouch design with accent tooling, wet formed, dyed black and hand stitched. Sheath is hot finished with a mixture of beeswax/paraffin/NFO, then multiple coats of Johnson's Paste Wax is applied and buffed.

The display box was made by me, stained and lined with faux fur.

Dimensions:

Total Length: 7"

Blade: 2 3/4"

Thickness: 5/32"

***NEW PICTURES ADDED***

There is one tiny spot on the left hand side of the blade that I am pretty upset about. I was finishing the jimping with the carbide cutter (will use files next time, that thing is too unruly), and set the knife down next to the dremel. Some how, when I sit back down I bumped the knife and the cutter nicked the blade and left a small spot on the ricasso. Too deep to get out without multiple sandings, it'll just have to serve as a beauty mark and a reminder to always be careful when working in the finishing stages.

I really wish I had a better photo setup, but I needed to get pics on tonight. I'll try to get some natural light pics outside tomorrow, those tend to look the best. It looks MUCH better in person, lol. I hope the new owner enjoys it.