J. Doyle

Dealer - Purveyor

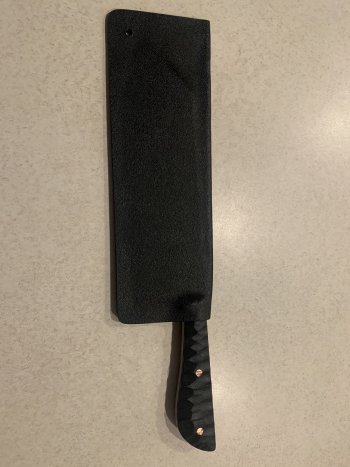

I’m using an OBM 2x72 grinder. I had the stock platen that I used for a while but I recently swapped it out for a KMG platen. The KMG offers substantially more room to get around the sides of the platen and the backer itself is thicker and heavier. Here are a couple pics of my set up.

Is the grinder variable speed....like with a VFD?

Also, putting a piece of glass over that platen will help a lot.

I also wanted to mention.....there is a place and time for softer platen backers and low grit gator belts.....but you want to be careful there. They can wash out crisp lines and grinds and give deceiving results that can create problems down the road.

I'd like to politely encourage everyone to try to correct and minimize mistakes, especially in the area of basic knife fundamentals, rather than figure out ways to hide them.

Don't get me wrong, there comes a time when its appropriate to attempt to hide mistakes and flaws too, I just dont feel that time is with the fundamentals of a good knife.

Directed at no one in particular.