Chuck Gedraitis Knives

Well-Known Member

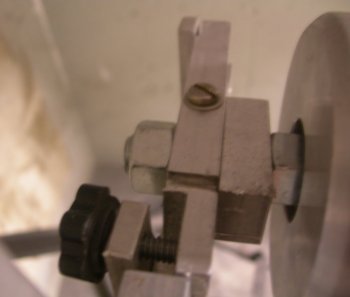

I finally converted my surface grinder to run belts. I can easily put the stone back on if I have to. I was waiting on the serrated wheel which arrived today. It is 1in wide, 6in diameter and 95duro. I borrowed the tracking design for the idler wheel from my Bader BIII. The upright, arm and tracking assembly I milled from 1/2 aluminum. This runs a 1X42 belt. It took a little tweaking to get it to track properly but it now works great.

The first pic is the old grinder and the next few are how it looks now.

Thank for looking,

Chuck

The first pic is the old grinder and the next few are how it looks now.

Thank for looking,

Chuck