Chris Railey

Well-Known Member

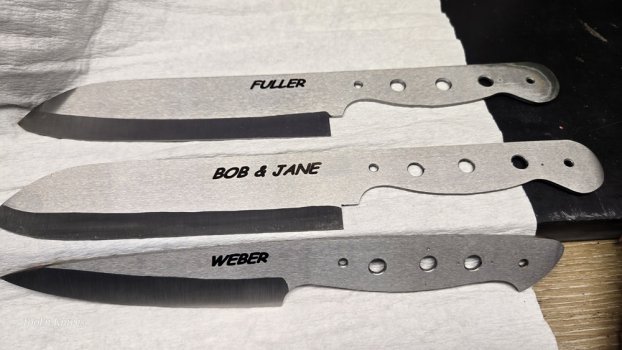

I have no regrets from buying mine. I know one like Gene has would do a better etch and last longer in the long run but I am satisfied with the job mine does very easily. My main justification, in case it helps you, was because it is a multi-use tool. I mark my name on my knives, make designs or custom markings on knives, use it to cut sheaths out perfectly, I can etch the sheaths, I can computer design knife templates and cut them out of wood or plastic stuff perfectly. I save leather by test cutting cardboard (free) first and see how it fits together, then use leather. I have not even gotten into the non-knife related stuff you can do with a CNC laser too.