I am new to knifemaking. I think i know how to make deer antler hidden tang knives. Looks pretty straight forward. But i can't find any info on how to properly make scales out of them for full tang knives and folders. What part of the antler is best for this (whitetail). How to smooth them out with out taking all of the natural 'ridges and valleys' out of them? and what else might need to be done? I may be over thinking this, but any help would be appreciated.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How to do Deer antler scales?

- Thread starter mxlj

- Start date

McClellan Made Blades

Well-Known Member

I am new to knifemaking. I think i know how to make deer antler hidden tang knives. Looks pretty straight forward. But i can't find any info on how to properly make scales out of them for full tang knives and folders. What part of the antler is best for this (whitetail). How to smooth them out with out taking all of the natural 'ridges and valleys' out of them? and what else might need to be done? I may be over thinking this, but any help would be appreciated.

mxlj,

I'm probably not the best to give advice on this subject but I made one with antler material for scales, although I know I got real lucky with the scales I chose. They ended up fitting perfectly, with a little help from some hot water and some flat sanding. The first thing is pick out some scales that will fit your tang with out having to remove a lot, you will have to remove some, no matter what, keep a close eye on any bends in the tang or the hron if they don't work with each other they WON'T work with each other. Also note the width of the tang and the width of the horn, they have to be fairly close or I think it might be difficult to get them to match up. Try not to pick any with wild bends or "sticker" points on them, it can make cutting hard. Experienced hands can pull that off, personally I wouldn't try it yet. Now find the center, on each end and make a careful cut on your bandsaw, I recommend a sharp blade, (read new here), it will make a better cleaner cut, and less likely to bounce like mine did, BE CAREFUL, cutting horn can be dangerous! Now that you've got it splt, flat sand both sides, until they are both completely flat, ther eis no short cut for this step both sides have to be completely flat, tape you some sand paper on some sort of surface that you know is flat and sit there with your material on the flat side, rubbing in a figure "8" pattern until you have it completely flat on every part of it. Do both pieces, also make sure your tang is perfectly flat, if you did it by stock removal, and you started with precision ground steel it should be in good shape, if it's not you have to make sure it's flat, th easiest way is to take your horn you've flattened and put them on the tang like you have them planned out hold them on the tang and hold the whole thing up to the light, a little pressure is OK a lot is not. If you can see light through the gaps in the horn and the tang it is not flat, either the horn needs more work or the tang isn't flat. Once you have a light free gap drill your holes for your pins where you want them, clean up the horn and the tang, Isopropyl alcohol is best, a good epoxy preferably the slow curing type, or whatever you like, glue t up and once it's done curing, shape the handles like you want, be careful and go slow at this part. This is the down and dirty version, but ecentially what I did when I made mine. Hope this helps, Rex

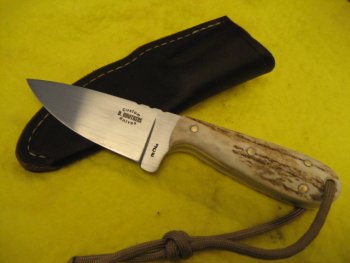

BTW I've included a pick of the one I made, to date this is the first and only one I've ever done, it was fun, difficult but fun.

Tip, if your having problems with any part of the fit up, you can boil the horn material, which will make it soft and pliable, practically bendable, I got mine pretty warm and then clamped it to the tang until it was cool and dry, usually it will stay like it was clamped.

Attachments

McClellan Made Blades

Well-Known Member

thank you very much. and beautiful looking handles- McClellan Made Blades.

Just call me Rex, And thank you, I made that knife for a buddy that stepped up to help me, like so many that enter the knife making world, they are stunned at how the established makers will stop what they're doing to help a newbie. I made myself a promise because of so many people that have helped me, that I would help anyone, every chance I had, kinda like "paying it forward", that knife was my first forged knife I dedicated it to Charlie (Edmondson) because he gave me so much of his time, materials, and more than anything, his friendship, and the later I don't take lightly. I know a lot of people but very few will I call a friend. Knifemakers are funny group of folks, but the commaradrie is like nothing I have seen anywhere...even in the MARINES! To be included in this group of folks is an honor to me, because they are cut from the finest fabric "man" has ever known, they are built like they used to be...like during my grandfathers time. When they say something, generally expect it to happen, barring unexpected circumstances, which most will contact you and say that something came up, Rex

DLBrothers

Well-Known Member

MX -I'm not certain exactly what you are looking to do since you mentioned both hidden tang and then making scales - which are two different things. However, it looks like from the response you are looking to do a full-tang knife with antler scales. This I have done several times with whitetail and other types of antler. There are several things to keep in mind: The size of the knife tang (depth) dictates the size of antler needed as well as the amount of bark you want to leave intact. For instance, for a typical hunter with a 5" handle of about 2" depth- it takes a VERY large diameter whitetail horn- Im talking B/C 6" base stuff. If you don't get that, you will end up with very round, un-comfortable scales on a very narrow handle and you will have pith issues to deal with on the front and rear of the scales as well as having a lot of pith in general.

It hard for me to explain this with out hand-on visualization. My advice for you would be first to purchase some scales from Axis deer before cutting that special shed or antler. I have screwed up more than one antler.

Now if you are wanting to do a hidden tang, then there are a whole different set of requirements to consider..... we can talk about that too if that is what you want.

It hard for me to explain this with out hand-on visualization. My advice for you would be first to purchase some scales from Axis deer before cutting that special shed or antler. I have screwed up more than one antler.

Now if you are wanting to do a hidden tang, then there are a whole different set of requirements to consider..... we can talk about that too if that is what you want.

Attachments

Just call me Rex, And thank you, I made that knife for a buddy that stepped up to help me, like so many that enter the knife making world, they are stunned at how the established makers will stop what they're doing to help a newbie. I made myself a promise because of so many people that have helped me, that I would help anyone, every chance I had, kinda like "paying it forward", that knife was my first forged knife I dedicated it to Charlie (Edmondson) because he gave me so much of his time, materials, and more than anything, his friendship, and the later I don't take lightly. I know a lot of people but very few will I call a friend. Knifemakers are funny group of folks, but the commaradrie is like nothing I have seen anywhere...even in the MARINES! To be included in this group of folks is an honor to me, because they are cut from the finest fabric "man" has ever known, they are built like they used to be...like during my grandfathers time. When they say something, generally expect it to happen, barring unexpected circumstances, which most will contact you and say that something came up, Rex

Thank you again for the info, Rex. Yes the few people i have talked to in the knife community seem to outstanding people, Larry

MX -I'm not certain exactly what you are looking to do since you mentioned both hidden tang and then making scales - which are two different things. However, it looks like from the response you are looking to do a full-tang knife with antler scales. This I have done several times with whitetail and other types of antler. There are several things to keep in mind: The size of the knife tang (depth) dictates the size of antler needed as well as the amount of bark you want to leave intact. For instance, for a typical hunter with a 5" handle of about 2" depth- it takes a VERY large diameter whitetail horn- Im talking B/C 6" base stuff. If you don't get that, you will end up with very round, un-comfortable scales on a very narrow handle and you will have pith issues to deal with on the front and rear of the scales as well as having a lot of pith in general.

It hard for me to explain this with out hand-on visualization. My advice for you would be first to purchase some scales from Axis deer before cutting that special shed or antler. I have screwed up more than one antler.

Now if you are wanting to do a hidden tang, then there are a whole different set of requirements to consider..... we can talk about that too if that is what you want.

Thank you, i will look at Axis deer. I diffidently need to practice on some, just looking for some direction before i get started.

John Andrews

Well-Known Member

I have a solution for flat antler scales that works great for me. I hot glue the handle piece of antler onto a square piece of wood and rip the antler on my tablesaw. Using a few SPOTS of glue, the antler is easily twisted off the pilot wood. You just need enough glue to safely hold the antler through the ripping process on the saw. Don't stand directly behind the piece being ripped, for safety's sake.

It's a safer and quick way to cut the antler into two flat pieces that are nice and flat, plus just rough enough to glue up well on the tang.

It's a safer and quick way to cut the antler into two flat pieces that are nice and flat, plus just rough enough to glue up well on the tang.

Diamond G Knives

Well-Known Member

John

I do the same thing. Ill orient the antler to the bandsaw blade then hot glue it to a piece of 1/8 wood paneling scrap. The slick side down. the rough finish on the back helps hold the glue, and the slick finish slides really well on the saw table.

Ive found this to the the easiest with the best success ratio, as well as THE BEST at keeping your fingers away from the blade!

Good Luck and God Bless

Mike

I do the same thing. Ill orient the antler to the bandsaw blade then hot glue it to a piece of 1/8 wood paneling scrap. The slick side down. the rough finish on the back helps hold the glue, and the slick finish slides really well on the saw table.

Ive found this to the the easiest with the best success ratio, as well as THE BEST at keeping your fingers away from the blade!

Good Luck and God Bless

Mike