Mark Barone

Well-Known Member

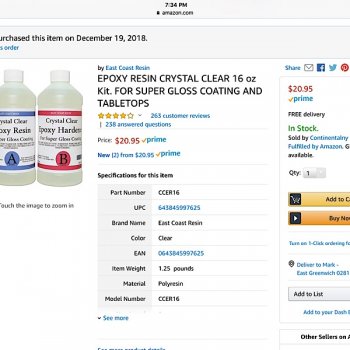

I have seen some beautiful worthless wood and resin scales. I never even heard of the term "worthless wood"before that. The problem is if you don't have access to worthless wood, it's expensive. Go figure! Anyway I decided to get a piece of zebra wood and create a worthless wood/ live edge feel to it and cast resin with it. I am not particularly happy with my first try. I had a two tone resin thing going on, but the green and blue blended in the drying process. I also don't have a vacuum chamber and used a blow dryer to remove bubbles. It seemed to work. Now I just have to make another knife.