Daniel Macina

Well-Known Member

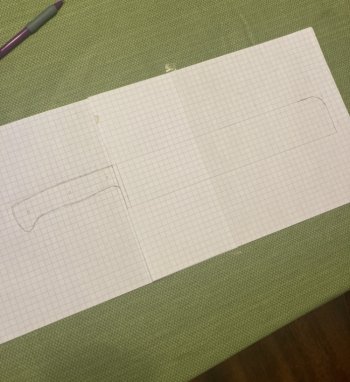

The Texas knife makers Guild has a hammer in next month and there will be a cutting competition and I think I will take a competition chopper. Has anybody made one that can give any kind of tips on the geometry? Looks like most of them are flat ground with a convex edge. It looks like in some of my research the part towards the Ricoso is ground more for chopping the tip more for slicing and the middle kind of somewhere between those two geometry‘s. Does that sound about right? Any tips or discussion is appreciated