Kevin Zito

KNIFE MAKER

My advice.... flip a coin. I’m still “deciding.”

Awesome!!I did the build and I have never regretted it! The one thing about building your own you have to have the knowledge to understand what you are looking at on the plans. Square is critical for the machine to run and function as it should!! Close is not close enough. You are not playing horse shoes or hand grenade's! If you realize at some point the last element you added is off. Stop and fix it, If it costs you a whole day in the build. Because the machine will not function and you won't ever be happy with it! Square and True!!!

Actually over the weekend while the forum was down I found this in a book mark I had. It is on another forum but you should be able to see the plans. If you can't and you want to use this build I will find someway for you to see it!!!

You should be able to see these, I am not signed in and I can see them!

http://www.customknifedirectory.com/forum/showthread.php?s=9646b315214cfcd4a7b06aaff50e1d8b&t=62944

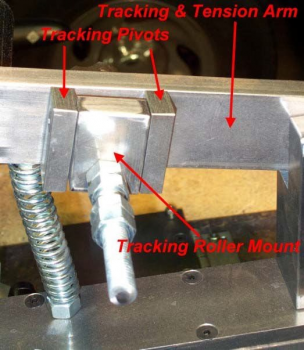

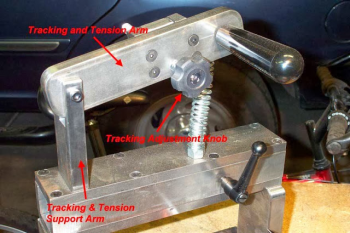

Those plans are very detailed and pictures of the actual build which helps to figure out the drawings. I built mine of steel although the one thing about aluminum is, it is lighter, no rusting, etc. However aluminum is going up everyday with the new tariffs!!

I have a buddy that has a CNC plasma table, I bet I could get him to cut the parts for me

I've had experience with the ratcheting belt tension mechanisms, and for the most part they are great. Notice I said "for the most part"..... where I came to dislike them is when using J weight belts..... I'd grind a bit, and any J weight belt would have to be retracked back to center, time and time again. I finally figure out what was going on..... as the belt heated up, it would stretch to the limit of the small spring that was suppose to keep it tight, and because of the "ratchet" mechanism, it would reach the limit of it's ability to hold the belt tight. At first I thought no big deal, just reach up and give the ratchet adjustment another click or two..... that was until I did that with a mylar backed belt..... it flew off the machine

And for me the ratchet is a must. I wouldn't consider a grinder without it. I've used a lot of J-Flex and have never had an issue with tracking or belt breaking. Try both grinders if you can, see what works best for you.Glad you mentioned about the ratcheting system - I'd been thinking I wanted to add that to my grinder. Then I read another place about the J weight belts stretching under use, and with your confirmation I think I'll pass on the ratchet system. Ed, you've saved me some work. Thanks.

Ken H>

Another thing with building vs. buying is resale value. I could put my grinder up for sale right now and probably have it sold by lunch. Recouping much of my money.

A home built machine is the opposite IMO. Myself, I would never buy a homemade machine from anyone. Other than for parts. You'd never know what you're getting.