Archer Moon

Well-Known Member

Do to bad equipment, bandsaw broke. I now am going thru my small stash of scales. I will get it all glued up tonight.

It reached 35 at my house. LolCold? In Oregon? Has not been over 32 for three days. 15 degrees at 7 this morning. Not much of a brake for a few days. Or a week.

That's too bad, Those things happen though(I have piles of those screw ups!)Im out. Screwed up the flippin guard and not able to replace in time. Sorry yall.

Here's my entry, finally done. Sheath is cut, tooled, and dyed. If it dries enough, I'll stitch it tomorrow. Anyway, here's the specs and my answer to Darrin's challenge of trying something new.

First time with this pattern. (inspired by a Randy Haas knife, with his permission)

First tapered tang.

First mosaic pins. (from someone at KC show, can't remember name)

First fiber liners. (from Pop's at KC show)

First jigged bone scales. (from Pop's at KC show)

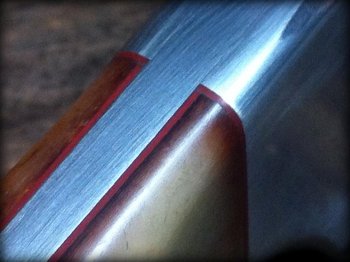

First peened bolsters. (304 SS)

Blade steel is A8 tool steel at 59-60rc. (very similar to D2, IMO, known for it's toughness, has some chromium, but not enough to be called SS)

Sorry, I forgot to measure the length, but its the perfect midsize hunter or EDC.

View attachment 57311 View attachment 57312 View attachment 57313 View attachment 57314 View attachment 57315

I feel the same way!I agree Brandant! I went back an looked at the pics this morning and there's some good stuff here. I'm kind of paranoid about mine, I don't think I've ever really had another "maker" examine a knife of mine. I showed my friction folder to Calvin and Justin at KC, but that's it. Mine's not perfect, but then again I don't think I'll ever make one that I can call perfect, there's always something.

That being said, I would like it if the maker that ends up with mine would give me a review. You won't hurt my feelings, I know I've still got a lot to learn and get better at. I need some brutal honesty, so don't hold back, it'll only help me in the future.