JRB Blades

Well-Known Member

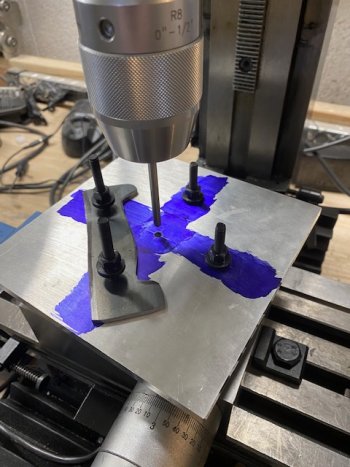

I am waiting to get my milling machine (3 weeks UGH!). In the meantime I am stockpiling the stuff I need to make some linerlock/frame lock knives and designing folders on draftsight. I have made my first liner lock and now am hooked! I bought a rotary table for my milling machine and bought a 6"x6" piece of precision ground aluminum and will bolt this to the top of my rotary table. To center my rotary table, I know I am supposed to use a dial indicator, but my rotary table has a MT2 hole in the center. I bought a lathe dead center with a MT2 taper on one end and a 3/4 shaft on the other. I was planning on putting the MT into the rotary table and a 3/4" collet in my mill and center it that way. As far as centering the piece of aluminum, I will drill a #15 hole in the center of it, ream it to a 3/16" (same as my pivot). Then using a precision drill rod in my collet, I'll center the aluminum plate (if it isn't already centered from the arbor trick). This way I can get exact measurements with the DRO to get my stop pin track milled out. I'll put a pivot through my liner and into the reamed hole in the aluminum and clamp the liner down and mill the track with a 9/64" end mill so that the track is . 015 thicker than my 1/8" stop pin, giving my .0075 on each side of the stop pin while it's moving in the track.

I hope this makes sense to yall, if you see any area for improvement or if this is a horrible idea, please let me know.

Pics of my first liner lock included...

I hope this makes sense to yall, if you see any area for improvement or if this is a horrible idea, please let me know.

Pics of my first liner lock included...