Mark Behnke

Well-Known Member

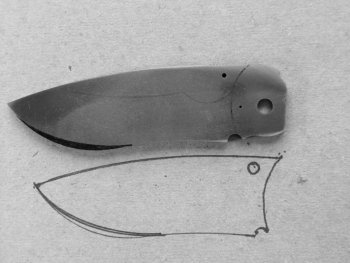

Received my kit this week, this dog is BIG, good it's going to be my EDC.

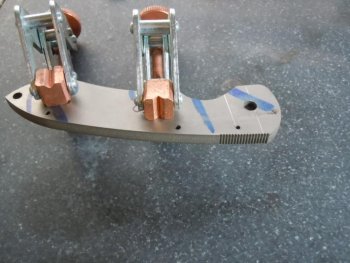

Here's some of the tools used.

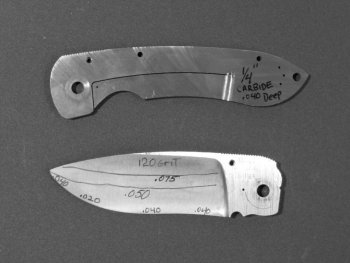

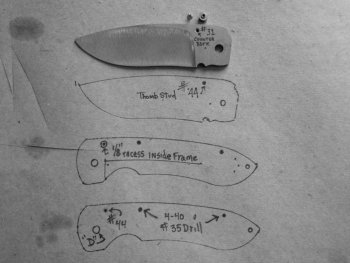

First thing, measure everything and record for reference.

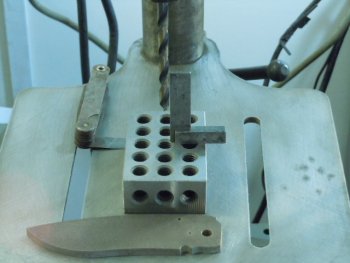

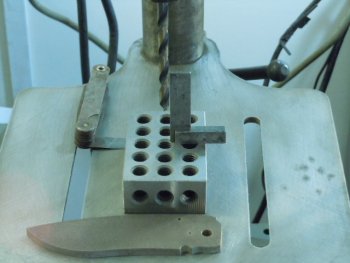

Drill and ream frame for pivot pin, but first I need to square the drill press table to the spindle.

Flat, square and parallel, very important in knife making.

I used a 123 block shimmed with a feeler gage bolted to the table.

The parts are so precision cut that I just aligned edges clamped and ready to drill

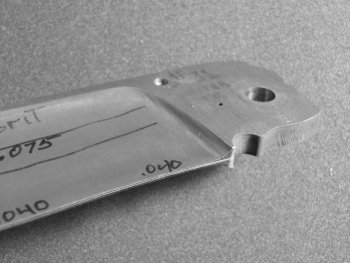

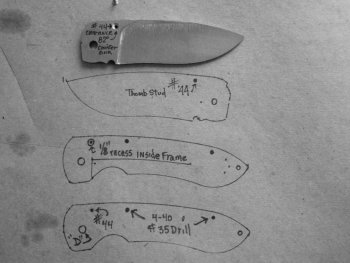

Drilled the pivot pin hole in the frame with a "D" letter drill and reamed with 1/4" reamer, The stand off holes were drilled to a #35 drill for a tight clearance for the 4-40 screws and the stop pin to a #44 for the 2-56 screws, the inside of the frame at the stop pin was drilled with a 1/8" drill for the recess

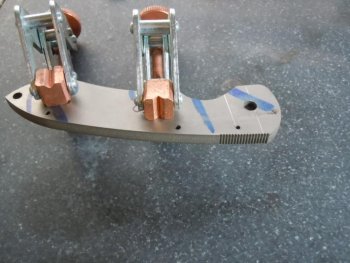

I said it was big, but how big? I weighed it, liners first then blade. Frame 98grams

Blade and frame before grind 216 1/2 grams

I plan to do a deep hollow grind that will reduce weight a lot but haven't decided on that yet.

Here's some of the tools used.

First thing, measure everything and record for reference.

Drill and ream frame for pivot pin, but first I need to square the drill press table to the spindle.

Flat, square and parallel, very important in knife making.

I used a 123 block shimmed with a feeler gage bolted to the table.

The parts are so precision cut that I just aligned edges clamped and ready to drill

Drilled the pivot pin hole in the frame with a "D" letter drill and reamed with 1/4" reamer, The stand off holes were drilled to a #35 drill for a tight clearance for the 4-40 screws and the stop pin to a #44 for the 2-56 screws, the inside of the frame at the stop pin was drilled with a 1/8" drill for the recess

I said it was big, but how big? I weighed it, liners first then blade. Frame 98grams

Blade and frame before grind 216 1/2 grams

I plan to do a deep hollow grind that will reduce weight a lot but haven't decided on that yet.

Attachments

Last edited by a moderator: