Bill Hubbell

KNIFE MAKER

Looking for input-

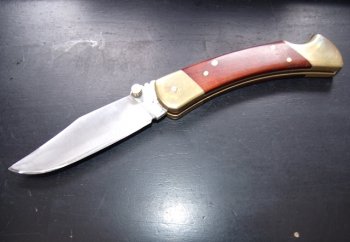

I am making a new blade for a lock-blade folder that my wife gave me about 30 years ago for an anniversary present. I was stupid enough back then to let a hardware store employee 'sharpen' my knife. He destroyed it, and it's been sitting in my drawer ever since.

I've never done anything with folders.

I have the blade ground close enough for heat treat. It's 1084, a shade over 1/8 thick right now (the ricasso/hinge area). That leaves me .015 to play with after heat treat to get it to the thickness of the old blade.

I'm nervous about loosing too much to scale during heat treat. I was told that coating it with ATP before heating it up would help. I only have my gas forge- no electric. I'm also wondering of I would be better off to heat it with my acetylene torch instead of the forge. -seems like I could be more careful of the thin edges. I don't have a rosebud tip, but thought maybe if I adjust it to be sure it's a carbonizing flame- not too intense, it might work ok. ???

Also thinking it would be harder to read the temp if it's coated, and also wondering why coating it wouldn't alter the quench process. I planned to take it just past non-magnetic, and quench in canola/peanut oil, since that's what I have, and have used before.

So, as you can see, I'm full of questions. Any help or advice will be appreciated. Thx, Bill

I am making a new blade for a lock-blade folder that my wife gave me about 30 years ago for an anniversary present. I was stupid enough back then to let a hardware store employee 'sharpen' my knife. He destroyed it, and it's been sitting in my drawer ever since.

I've never done anything with folders.

I have the blade ground close enough for heat treat. It's 1084, a shade over 1/8 thick right now (the ricasso/hinge area). That leaves me .015 to play with after heat treat to get it to the thickness of the old blade.

I'm nervous about loosing too much to scale during heat treat. I was told that coating it with ATP before heating it up would help. I only have my gas forge- no electric. I'm also wondering of I would be better off to heat it with my acetylene torch instead of the forge. -seems like I could be more careful of the thin edges. I don't have a rosebud tip, but thought maybe if I adjust it to be sure it's a carbonizing flame- not too intense, it might work ok. ???

Also thinking it would be harder to read the temp if it's coated, and also wondering why coating it wouldn't alter the quench process. I planned to take it just past non-magnetic, and quench in canola/peanut oil, since that's what I have, and have used before.

So, as you can see, I'm full of questions. Any help or advice will be appreciated. Thx, Bill