izafireman

Well-Known Member

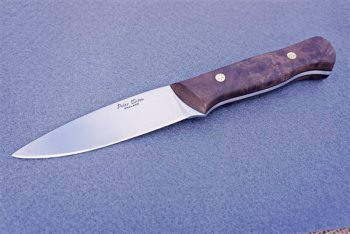

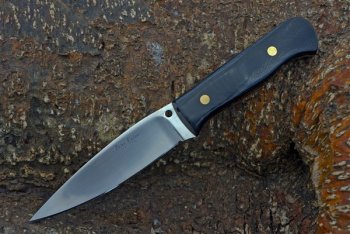

Well as I have been here asking for tips over the last few months I thought I had better put some of my knives up. Some a these were done after I got the tips here on satin finishing use Ryhnowet papers which helped me a lot. All are Elmax HRC 61.