MTBob

Well-Known Member

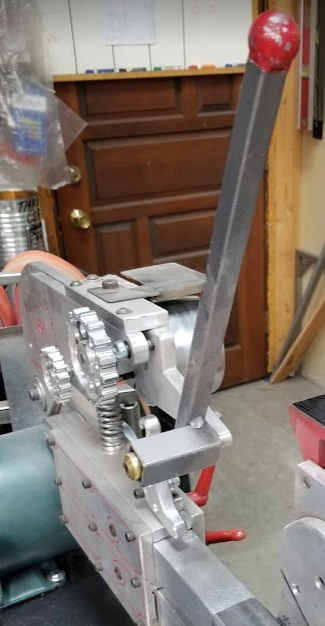

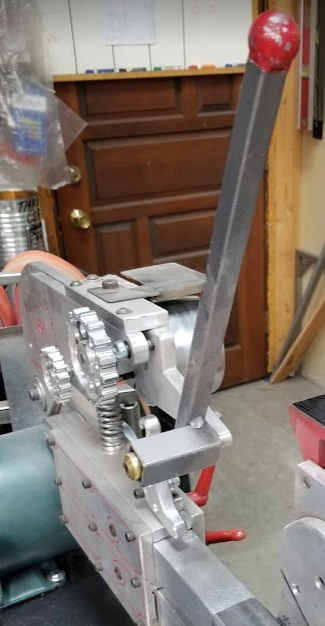

I've had my Reeder grinder about 3 years and have found it to be well built and very versatile. I've also found there are a number of modifications to the grinder that improves its operation. Most of the mods I've done on the Reeder are also applicable to other grinders.

Here's the first one:

Tension Arm Handle Extension - it seems most 2x72 tension arm handles are positioned like Reeder's, see the brass handle sticking out of the modified handle. Sticking out at 90 degrees this original handle requires an extended arm and downward pressure to release the belt and/or engage the tension latch. To me that handle position was really awkward and required use of the tension latch to remove and install a belt.

The new handle extension offers added leverage AND is in a position that is more compatible for arm movements - a pulling motion rather than a downward pushing motion . This handle extension eliminates the use of the tension latch, so I change belts using ONLY this handle to both remove and install a belt.

To install a belt I initially feed it around 3 pulleys, down across the platen, pull the handle down and feed it around the lower platen pulley. A quick, comfortable belt change.

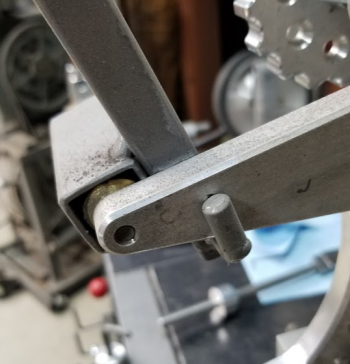

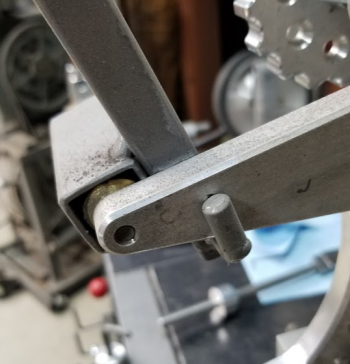

In certain grinding situations the handle can be in the way. So, I designed it to rotate around the original handle and lay back out of the way. It can also slide off if necessary.

Edit 11/20/21: Added the following photos:

I'll add another hack shortly.

Here's the first one:

Tension Arm Handle Extension - it seems most 2x72 tension arm handles are positioned like Reeder's, see the brass handle sticking out of the modified handle. Sticking out at 90 degrees this original handle requires an extended arm and downward pressure to release the belt and/or engage the tension latch. To me that handle position was really awkward and required use of the tension latch to remove and install a belt.

The new handle extension offers added leverage AND is in a position that is more compatible for arm movements - a pulling motion rather than a downward pushing motion . This handle extension eliminates the use of the tension latch, so I change belts using ONLY this handle to both remove and install a belt.

To install a belt I initially feed it around 3 pulleys, down across the platen, pull the handle down and feed it around the lower platen pulley. A quick, comfortable belt change.

In certain grinding situations the handle can be in the way. So, I designed it to rotate around the original handle and lay back out of the way. It can also slide off if necessary.

Edit 11/20/21: Added the following photos:

I'll add another hack shortly.

Last edited: