Johan Nel

Well-Known Member

I have come in possession of a Carl Schlieper knife that needs some TLC.

From what I could gather on the internet, these knifes were mass produced and were sold en masse.

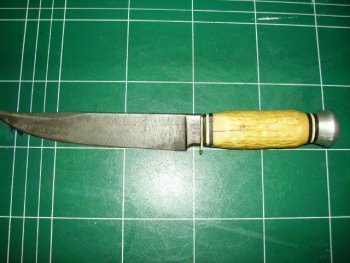

See the photo:

Overall quality of the photos is not great, sorry about that.

The design seems based on a Bowie with a false double edge. Overall length of the knife is about 250mm or 10 inches, with the blade being about 150mm (6 inches) and the handle 100mm or 4 inches. It has stamp on the one side of the ricasso that looks like a fanned out feeler gauge and the words "Carl Schlieper Solingen Germany" stamped on the other side. Steel is obviously a carbon steel of sorts. The tang is through the handle material and has a brass nut that screws onto the tang. Brass nut is sunk into the bolster. Front bolster is a brass plate, handle material seems to be stag or other horn with black & white spacers fore & aft. Handle is worn, but still fully functional.

The quality of workmanship is not great, but the steel seems fine and holds a good edge. The blade is coarsely finished with grind marks clearly showing.

The knife blade was quite rusted, but it cleaned up beautifully by inserting the blade in vinegar overnight and scrubbing all the crud off the next day. No serious pitting is evident.

The truely sad part of this story is that the tip of the blade is broken off and was done by nobody else but "mwoa" in an effort to straighten it. Bad move!

The knife still has much potential, so I thought of refurbishing the knife and do a few alterations to beautify it a but, or "dignify" it, is more my chain of thought. It is not a major collectors item, so I would not be damaging its monetary value in any way.

The things I plan to do are as follows:

Regards,

Johan Nel

From what I could gather on the internet, these knifes were mass produced and were sold en masse.

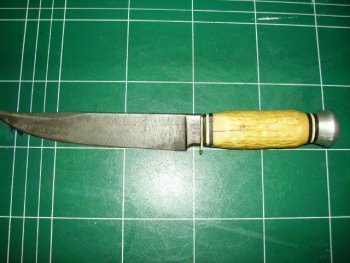

See the photo:

Overall quality of the photos is not great, sorry about that.

The design seems based on a Bowie with a false double edge. Overall length of the knife is about 250mm or 10 inches, with the blade being about 150mm (6 inches) and the handle 100mm or 4 inches. It has stamp on the one side of the ricasso that looks like a fanned out feeler gauge and the words "Carl Schlieper Solingen Germany" stamped on the other side. Steel is obviously a carbon steel of sorts. The tang is through the handle material and has a brass nut that screws onto the tang. Brass nut is sunk into the bolster. Front bolster is a brass plate, handle material seems to be stag or other horn with black & white spacers fore & aft. Handle is worn, but still fully functional.

The quality of workmanship is not great, but the steel seems fine and holds a good edge. The blade is coarsely finished with grind marks clearly showing.

The knife blade was quite rusted, but it cleaned up beautifully by inserting the blade in vinegar overnight and scrubbing all the crud off the next day. No serious pitting is evident.

The truely sad part of this story is that the tip of the blade is broken off and was done by nobody else but "mwoa" in an effort to straighten it. Bad move!

The knife still has much potential, so I thought of refurbishing the knife and do a few alterations to beautify it a but, or "dignify" it, is more my chain of thought. It is not a major collectors item, so I would not be damaging its monetary value in any way.

The things I plan to do are as follows:

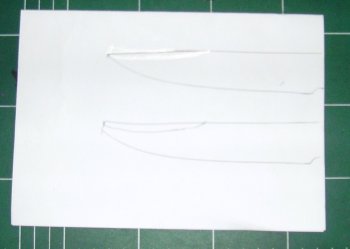

- Repair the tip of the blade by altering/filing the profile to form a proper tip again and reshape the bevels to properly fit.

- Neaten the overall look of the blade by removing all the coarse marks from it and define the false edge lines a little better and finish the blade to a 600 gritt.

- Try to lengthen the handle to about 120mm or 4 &3/4 inch. It is too small/short to comfortly fit in my hands, so that's the reason for that. Since the handle material won't quite fit anymore, I may need to change that as well. I will still see about the handle on the long run.

Regards,

Johan Nel

Last edited: