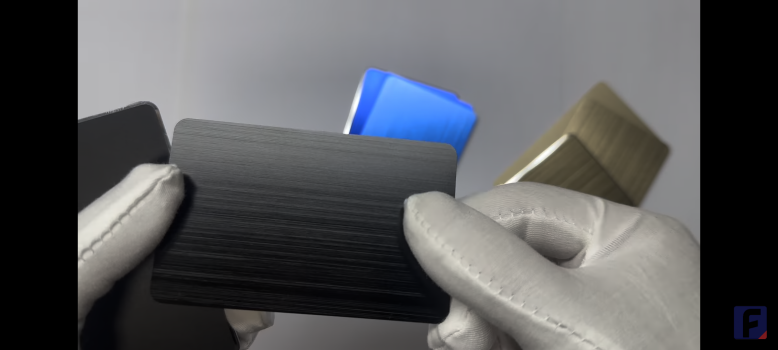

OK, I edited the above #97 thread to replace the "no paint" with another photo of the same etch but more in focus. You can see the first "no paint" photo looks better than before.

Darn if it doesn't almost look blacker than the "black paint" photo. Perhaps it's because the scale of the two photos are different? Really, looking at the two etches on the same blade there just isn't much difference in them. Remember the difference in speed. It does take a slower speed to get the same good etch as with the black paint. Paint allows a faster (quicker) etch than no paint.

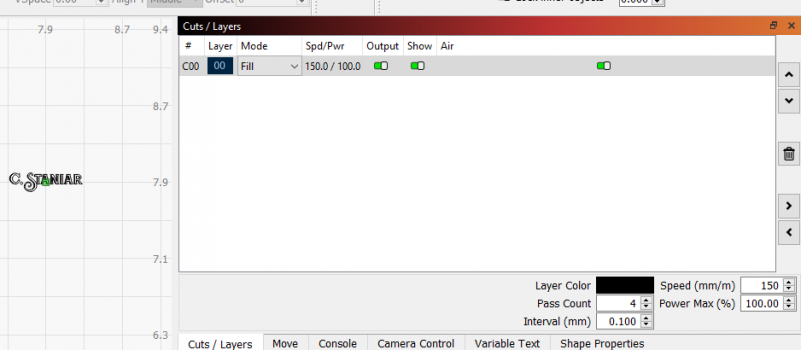

In the "no paint" photo you can easy see why that blade is in the scrap pile. Not sure why it cracked - it's AEB-L profiled only before HT'ing in oven at 1975°F, plate quenched, in freezer for 15 minute or so, then in LN for an hour or so, then in tempering oven at 325°F for 2 hrs, air cooled than back in oven at 350°F for 2 hr for a final of 61 Rc. I didn't notice the crack until the bevels were ground in as you see in photo.

Darn if it doesn't almost look blacker than the "black paint" photo. Perhaps it's because the scale of the two photos are different? Really, looking at the two etches on the same blade there just isn't much difference in them. Remember the difference in speed. It does take a slower speed to get the same good etch as with the black paint. Paint allows a faster (quicker) etch than no paint.

In the "no paint" photo you can easy see why that blade is in the scrap pile. Not sure why it cracked - it's AEB-L profiled only before HT'ing in oven at 1975°F, plate quenched, in freezer for 15 minute or so, then in LN for an hour or so, then in tempering oven at 325°F for 2 hrs, air cooled than back in oven at 350°F for 2 hr for a final of 61 Rc. I didn't notice the crack until the bevels were ground in as you see in photo.

Last edited: