I like learning about northern knives and pulling from traditional concepts.

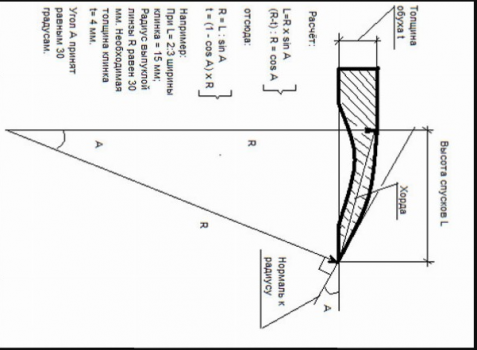

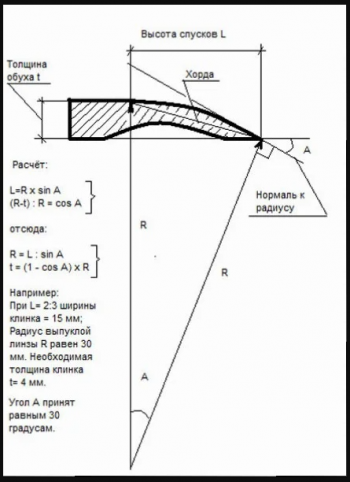

I'm intrigued about the grind on yakut knives so I'm going to make one. I don't know all the different ways, but I'm going for basic cross section. Still need to find out the edge spec. I think it tapers to nothing.

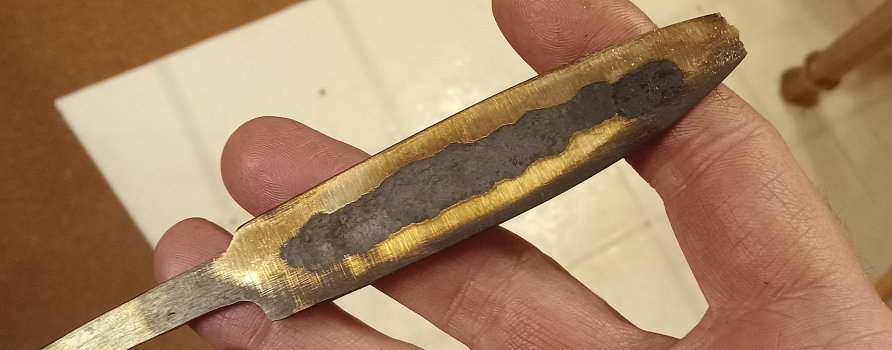

Here's my forging: I used a bearing race.

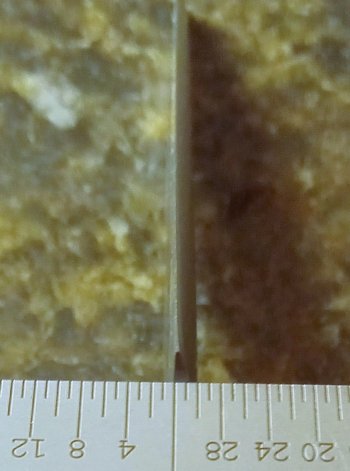

I discarded the top one. The bottom one had to go back into the forge to get more of a fuller.

I'm intrigued about the grind on yakut knives so I'm going to make one. I don't know all the different ways, but I'm going for basic cross section. Still need to find out the edge spec. I think it tapers to nothing.

Here's my forging: I used a bearing race.

I discarded the top one. The bottom one had to go back into the forge to get more of a fuller.