I have a book called Damascus steel, theory and practice by Schiffer. Some of the damascus he makes in the book he is using small square stock 1084 and 15N20. Does anyone know where you could by small sized square and or round stock of 1084 and 15N20. I've scoured the internet and come up empty. I buy most my steel form new jersey steel baron, he has some larger sized 1080 square stock but no small sized stuff

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Where do you buy small square stock 1084

- Thread starter myszka

- Start date

Raymond Richard

Forum Owner & Moderator

How small are you looking for? This outfit carries 1080 in square and hexagone: http://www.pmtsco.com/

EdCaffreyMS

"The Montana Bladesmith"

You'll likely not find either in small square sizes..... what many don't realize is that there is little to no "new" steel being created in this country..... and the little that is, comes in a very limited range of sizes/shapes. Unless something has changed, all the steel sold by NJSB is made in Germany to the specs of NJSB, and then shipped to the U.S....... that's why things are often in "sold out" status on the website. (waiting on the next shipment)

There was a time, long ago, when a person could find nearly any size/shape, of any steel type you wanted, but those days are long gone. My advice to anyone seeking steel, is that when you find what you want, buy just as much as you possibly can.... it won't go bad on the shelf, prices are only going to go higher, and you MIGHT not every find it again.

Very often these days, if I need specific sizes and/or shapes for forging projects, I have to create them myself by forging existing sizes/shapes into what I need, adding another step to the process. I often have clients who don't understand why I quote them the prices I do for specific designs/projects....... and it's because I sometimes have to spend DAYS reforging materials to the sizes/shapes necessary to create their request(s).

There was a time, long ago, when a person could find nearly any size/shape, of any steel type you wanted, but those days are long gone. My advice to anyone seeking steel, is that when you find what you want, buy just as much as you possibly can.... it won't go bad on the shelf, prices are only going to go higher, and you MIGHT not every find it again.

Very often these days, if I need specific sizes and/or shapes for forging projects, I have to create them myself by forging existing sizes/shapes into what I need, adding another step to the process. I often have clients who don't understand why I quote them the prices I do for specific designs/projects....... and it's because I sometimes have to spend DAYS reforging materials to the sizes/shapes necessary to create their request(s).

Drew Riley

Well-Known Member

You'll likely not find either in small square sizes..... what many don't realize is that there is little to no "new" steel being created in this country..... and the little that is, comes in a very limited range of sizes/shapes.

Little to no new "cutlery grade" steels maybe. Here in NW Indiana, we're still producing and processes millions of tons of steel per year, though a majority of it is automotive or structural steel.

When I worked for NLMK steel, they were making quite a bit of high carbon steel, including 1095, but it was all hot rolled for industrial applications, and likely no where near as suitable for knife making as the steel Aldo procures.

EdCaffreyMS

"The Montana Bladesmith"

Little to no new "cutlery grade" steels maybe. Here in NW Indiana, we're still producing and processes millions of tons of steel per year, though a majority of it is automotive or structural steel.

It's not "new" steel..... the stuff that's being turned out there is like everywhere else in the country.....it's "recycled" steel. I have family working steel from that area..... it's all remelted scrap. Both "automotive" and "structural" are just euphemistically renamed scrap steel. When I use the term "new"..... that means from scratch.

The way Aldo got started was when all the steel plants across the midwest/northeast shut down.....he was buying the ingots of carbon/alloy steel for pennies on the dollar, and when it ran out, he had no choice other then to have it made in Germany....because all the plants that make/made new/or those types of steel had gone under.

Drew Riley

Well-Known Member

It's not "new" steel..... the stuff that's being turned out there is like everywhere else in the country.....it's "recycled" steel. I have family working steel from that area..... it's all remelted scrap. Both "automotive" and "structural" are just euphemistically renamed scrap steel. When I use the term "new"..... that means from scratch.

The way Aldo got started was when all the steel plants across the midwest/northeast shut down.....he was buying the ingots of carbon/alloy steel for pennies on the dollar, and when it ran out, he had no choice other then to have it made in Germany....because all the plants that make/made new/or those types of steel had gone under.

It's true that almost all "new" steel has some amount of scrap in it, especially in the mini mills and EAFs, as you have to "prime" the arc furnaces, and it's much more cost effective to use scrap. That said, the larger mills like ArcelorMittal (formerly Bethlehem Steel) and US Steel still use raw ore and virgin metals for casting slabs.

At any rate, steel can be recycled very efficiently without compromising the end product, and the chemistry of the steel is still very strictly controlled and tested. Any scrap that is used will make up a relatively small percentage of the final product anyway (say 10% or so) in most cases, but from a cost/efficiency standpoint, it doesn't make sense NOT to use scrap.

As far as I know, this is how ALL steel is made, even in the European mills. Now, you do obviously have different kinds of scrap (what is known as "single origin scrap" for instance), and different methods of grading and sorting, how much goes in. etc... and not all steel is created equal by any means, but this is less a function of how much scrap was used, and more of what kind and how well the overall process was controlled, from heat, to casting, to rolling, etc...

Mini-mills (like where much of the cutlery grade steel is going to come) control this a little better. Smaller heats, better process control, higher grading standards, etc...

what many don't realize is that there is little to no "new" steel being created in this country.....

It's true that almost all "new" steel has some amount of scrap in it, especially in the mini mills and EAFs, as you have to "prime" the arc furnaces, and it's much more cost effective to use scrap. That said, the larger mills like ArcelorMittal (formerly Bethlehem Steel) and US Steel still use raw ore and virgin metals for casting slabs.

At any rate, steel can be recycled very efficiently without compromising the end product, and the chemistry of the steel is still very strictly controlled and tested. Any scrap that is used will make up a relatively small percentage of the final product anyway (say 10% or so) in most cases, but from a cost/efficiency standpoint, it doesn't make sense NOT to use scrap.

I wondered about this, myself. Question is, I know where there is about a quarter mile of 1" round (if I remember right) spring steel coiled up on the ground since about the 40 -50's at the latest. It's on private land and I'd have to ask for it, but I wonder if it's worth it to grab it? It looked ok - not rusted through or anything. Referring to what Ed was saying to buy up what you want when you see it - and it is enough to learn what the right heat treat is. It seems like I should use it up since it would just go to recycle someday anyway? I wanted to take advice to use known steel so I decided not to, but now maybe I should?

EdCaffreyMS

"The Montana Bladesmith"

That's always a tough decision, filled with questions. On one hand you could be getting usable material, but on the other hand, there is the question of what the material actually is. It's all risk and reward.... only you can decided.

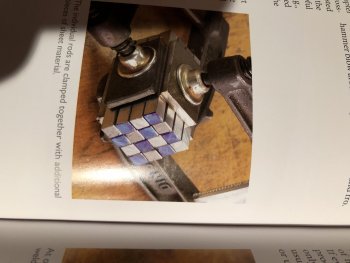

I'm familiar with that book... When it was first published, it, along with a couple of others spawned a fad of building what many called "precision" damascus. Many thought the methodology would reduce the amount of work it took to create given patterns, but in reality is doesn't.... it just shifts the workload from forging/manipulation of the materials, to the prep-work.

At that time, finding various sizes/shapes of the materials used in that methodology was much easier then today. Part of what we do (Bladesmithing) and how we go about, it is often determined on factors we cannot control..... and how we go about overcoming those factors.... or sometimes, IF we're willing to do what it takes to overcome them. It really all boils down to an individual's desire and determination. If both of those are present, then there's few things that you can't accomplish in the realm of forging...... there are many paths to the same destination.

I'm familiar with that book... When it was first published, it, along with a couple of others spawned a fad of building what many called "precision" damascus. Many thought the methodology would reduce the amount of work it took to create given patterns, but in reality is doesn't.... it just shifts the workload from forging/manipulation of the materials, to the prep-work.

At that time, finding various sizes/shapes of the materials used in that methodology was much easier then today. Part of what we do (Bladesmithing) and how we go about, it is often determined on factors we cannot control..... and how we go about overcoming those factors.... or sometimes, IF we're willing to do what it takes to overcome them. It really all boils down to an individual's desire and determination. If both of those are present, then there's few things that you can't accomplish in the realm of forging...... there are many paths to the same destination.

Drew Riley

Well-Known Member

I wondered about this, myself. Question is, I know where there is about a quarter mile of 1" round (if I remember right) spring steel coiled up on the ground since about the 40 -50's at the latest. It's on private land and I'd have to ask for it, but I wonder if it's worth it to grab it? It looked ok - not rusted through or anything. Referring to what Ed was saying to buy up what you want when you see it - and it is enough to learn what the right heat treat is. It seems like I should use it up since it would just go to recycle someday anyway? I wanted to take advice to use known steel so I decided not to, but now maybe I should?

Might not be a bad idea to grab a foot or two and do some testing, before committing to loading a couple hundred lbs of the stuff.

Drew Riley

Well-Known Member

Now that I see the picture, it made me think of this:

https://www.mcmaster.com/#key-stock/=1dkgblv

The "spring steel" key stock is 1095, not 1084, but certainly an option.

https://www.mcmaster.com/#key-stock/=1dkgblv

The "spring steel" key stock is 1095, not 1084, but certainly an option.