Burl Source

Forum Owner & Moderator

This thread was prompted by one from several months ago.

A knife maker was complaining and blaming the stabilizer for how a piece of wood turned out that he had sent in to be dyed and stabilized.

He never posted any photos so we will never know for sure if anything even went wrong. He said it looked dark on the outside and light colored inside.

I am posting these photos and explanation so you can know what to expect if you send in any wood to be dyed and stabilized.

The wood here was dyed and stabilized for me by K&G, (Knife and Gun Finishing Supply). I have been delighted by everything they have done for me.

All of these pieces are maple burl. All cut from the same burl. All of each color were done in the same batches.

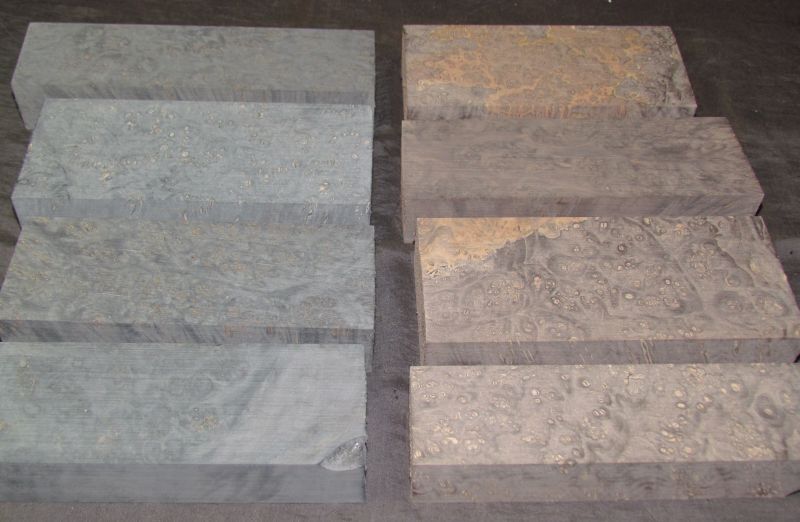

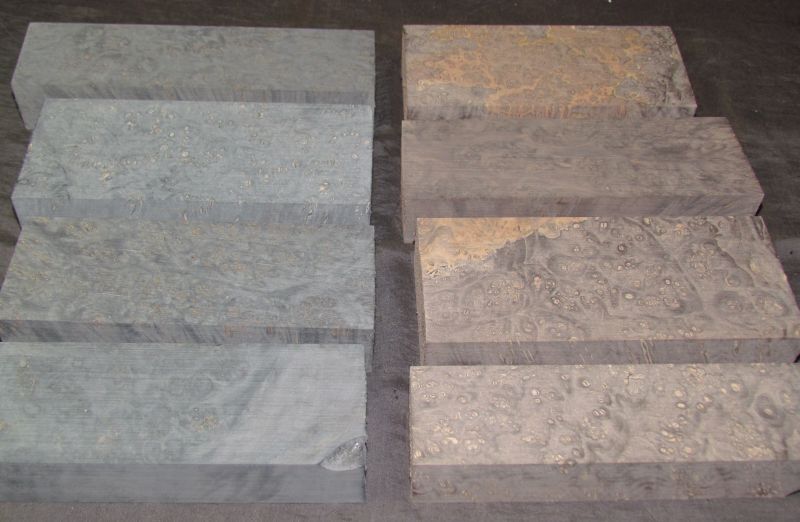

When the wood first comes back from being dyed first and then stabilized it looks like this. Very dark.

The exteriors are covered with gunk that may be a little sticky. This is excess resin with some pigment from the dye.

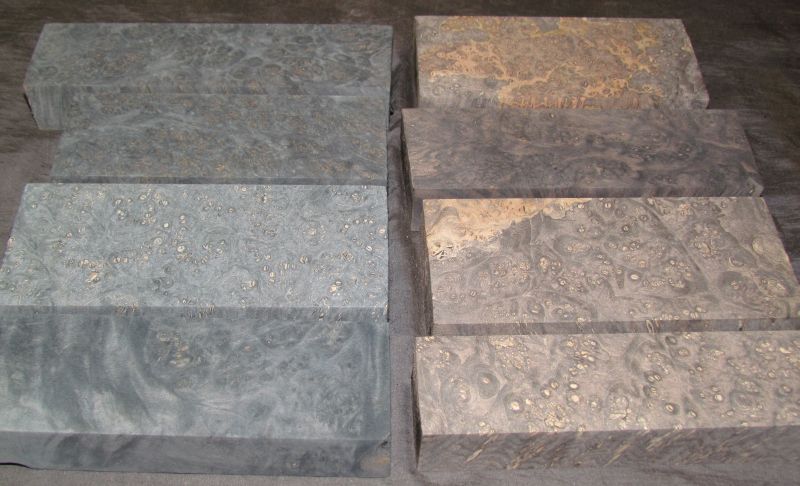

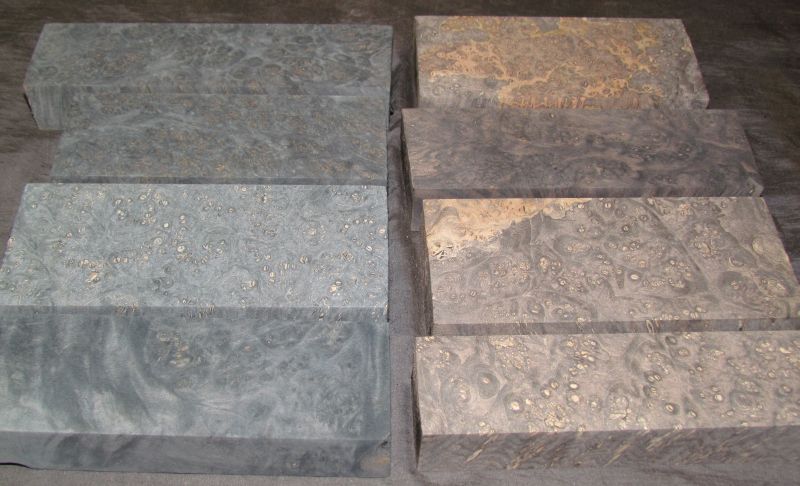

That outer rind is what causes most of the clogging and gunking up of your sanding belts. I remove the exterior with my sander using very course 36 grit. If you go much finer the belts or discs clog faster.

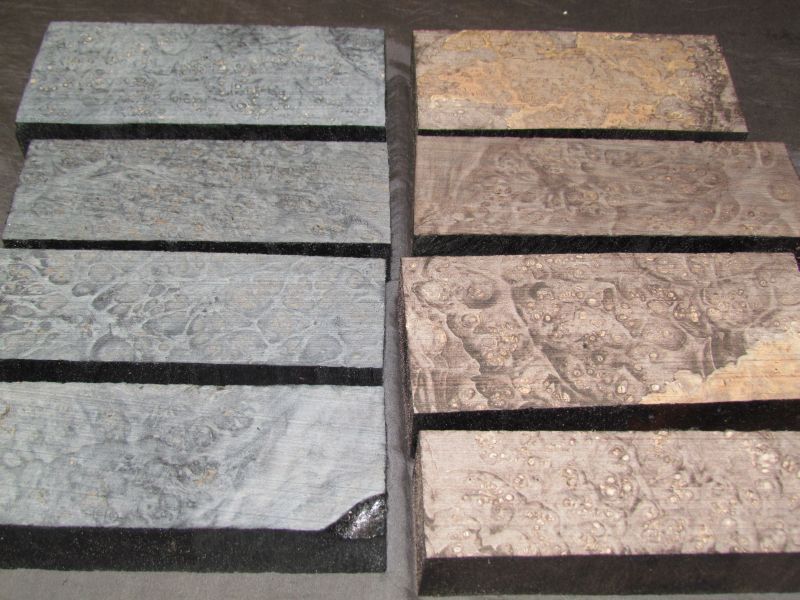

Then I go to 120 grit with the stationary belt sander.

Finally 220 grit with a palm sander.

You have probably noticed the blocks looking a little darker as you get to the finer grits.

That is because the coarser surfaces reflect the light differently hiding a lot of the color.

As you get a smoother surface the coloring and figure begin to stand out a lot more.

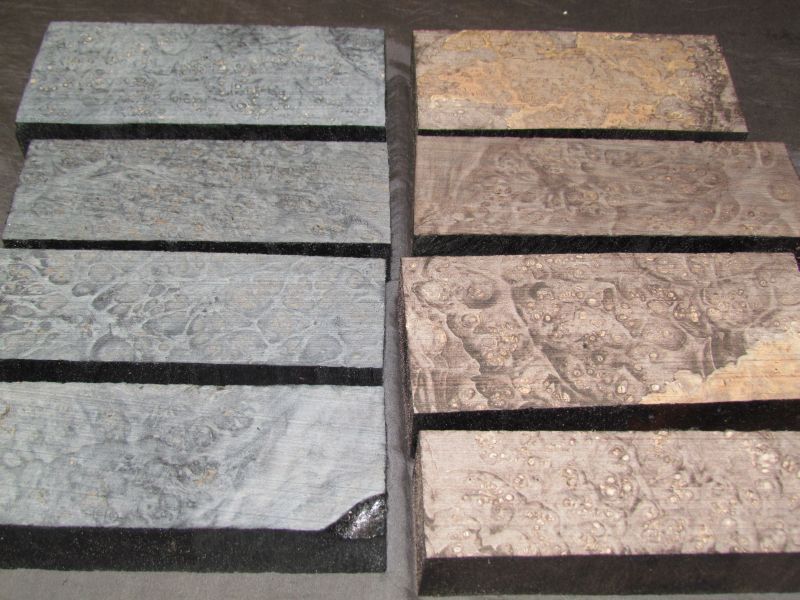

This is 220 grit and sprayed with a light coat of lacquer. Not quite as nice as it will look when a handle is properly finished. But enough to show some of the potential.

As a summary

The dyed and stabilized blocks will always look darker on the exterior before they are cleaned up.

Each piece of wood will react differently to the dye. It's dye not paint.

To make the most of the wood's potential you have to finish it correctly.

Most of the professionally stabilizing companies know what they are doing when it comes to dyeing and stabilizing wood.

Some woods just won't take the dye the same as others. If something looks wrong it may not be.

A knife maker was complaining and blaming the stabilizer for how a piece of wood turned out that he had sent in to be dyed and stabilized.

He never posted any photos so we will never know for sure if anything even went wrong. He said it looked dark on the outside and light colored inside.

I am posting these photos and explanation so you can know what to expect if you send in any wood to be dyed and stabilized.

The wood here was dyed and stabilized for me by K&G, (Knife and Gun Finishing Supply). I have been delighted by everything they have done for me.

All of these pieces are maple burl. All cut from the same burl. All of each color were done in the same batches.

When the wood first comes back from being dyed first and then stabilized it looks like this. Very dark.

The exteriors are covered with gunk that may be a little sticky. This is excess resin with some pigment from the dye.

That outer rind is what causes most of the clogging and gunking up of your sanding belts. I remove the exterior with my sander using very course 36 grit. If you go much finer the belts or discs clog faster.

Then I go to 120 grit with the stationary belt sander.

Finally 220 grit with a palm sander.

You have probably noticed the blocks looking a little darker as you get to the finer grits.

That is because the coarser surfaces reflect the light differently hiding a lot of the color.

As you get a smoother surface the coloring and figure begin to stand out a lot more.

This is 220 grit and sprayed with a light coat of lacquer. Not quite as nice as it will look when a handle is properly finished. But enough to show some of the potential.

As a summary

The dyed and stabilized blocks will always look darker on the exterior before they are cleaned up.

Each piece of wood will react differently to the dye. It's dye not paint.

To make the most of the wood's potential you have to finish it correctly.

Most of the professionally stabilizing companies know what they are doing when it comes to dyeing and stabilizing wood.

Some woods just won't take the dye the same as others. If something looks wrong it may not be.