Graham Fredeen

Well-Known Member

Hey Bruce,

Thought I might come over here and share one of my projects with everyone. Hope you don't mind.

I know I've gotten a lot of great valuable information and ideas from your past WIP threads, and always look forward to seeing them, so thought I'd share one that uses some things I picked up from your threads, and maybe pass along some things and ideas to others while I'm at it.

So folks, here we go:

Technically speaking this pattern will be a mosaic, based on a modifid W pattern that was re-squared on a 45° bias, 4-wayed, and then tiled out.

This pattern starts just like it would if you were making a standard W pattern, except for varying the layer composition of the billet.

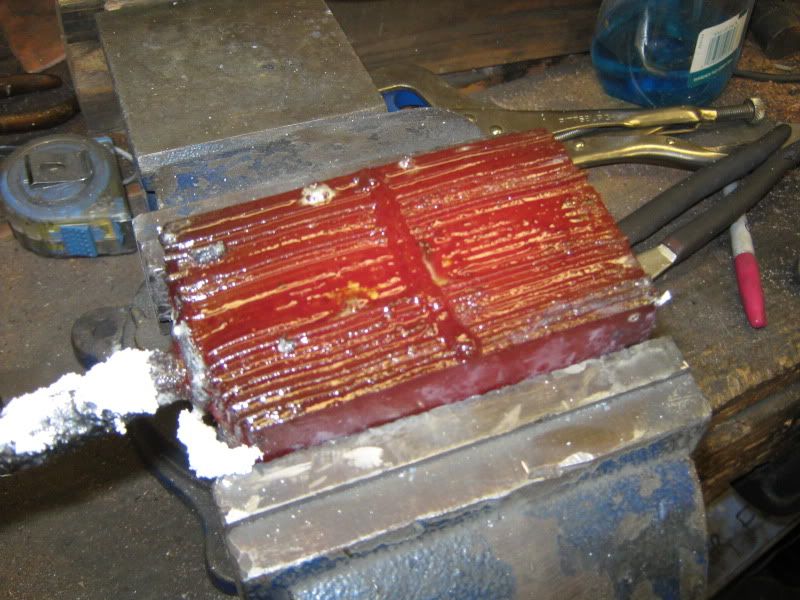

The starting billet:

18 layers of 1095 and 10 layers of 15N20. You'll notice that the middle of the billet is straight 1095, with alternating 1095/15N20 on the edges. This modification will create different thicknesses in layers and will add to the pattern development. Never underestimate what varying layer stacks/layer thickness can do for a pattern.

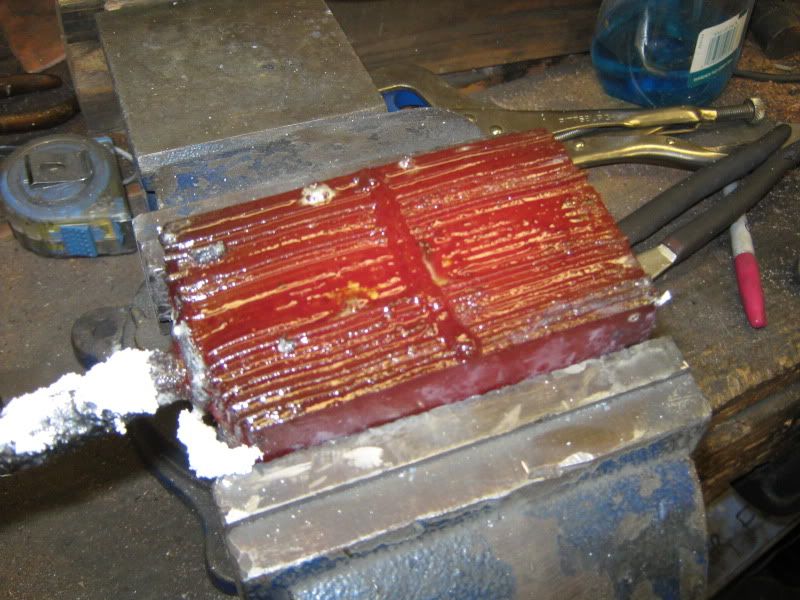

In for welding:

Right after the first welding press:

I grind off the mig welds to prevent billet contamination:

Forge things down into a rough square:

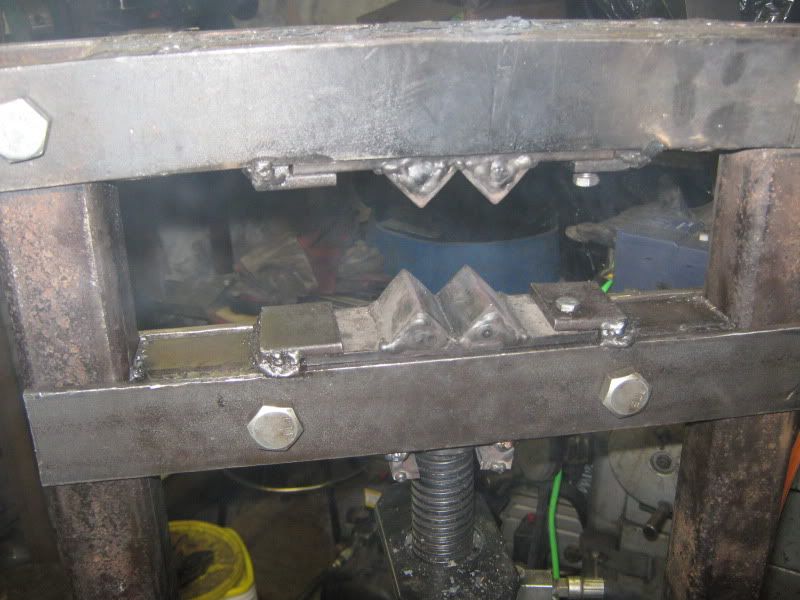

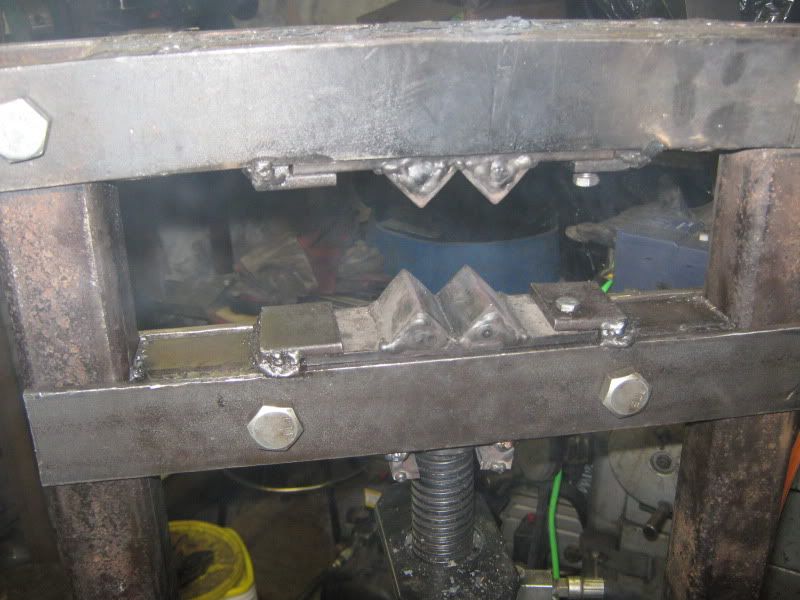

Next I'll use squaring dies to start squaring the billet on a 45° bias. This forces in the corners of the billet and starts distorting the layers for a sharper W effect. I picked up this from Bruce's W pattern thread.

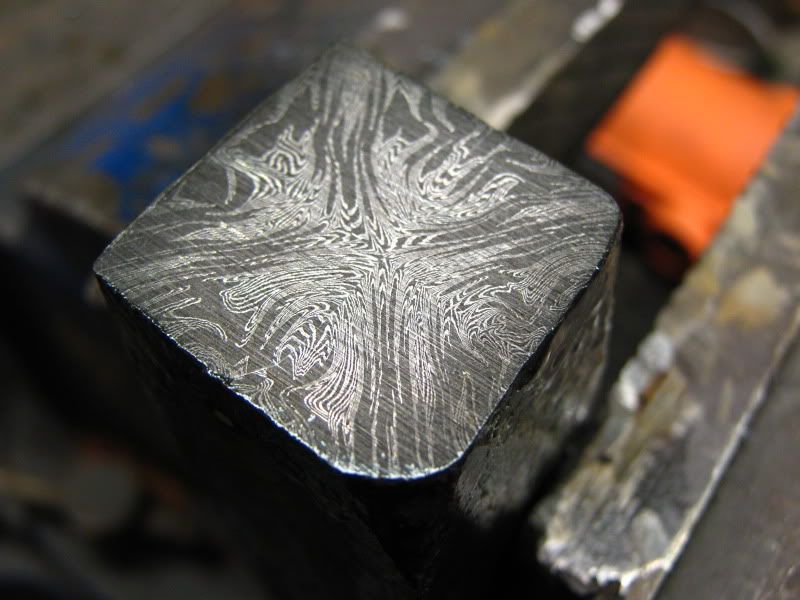

Here's the billet after the rough trip through the squaring dies:

The billet will now be rotated 90° from its original orientation and drawn out (the "distorted" layers are now in a "vertical" orientation):

The billet drawn out and ready for a cut and restack:

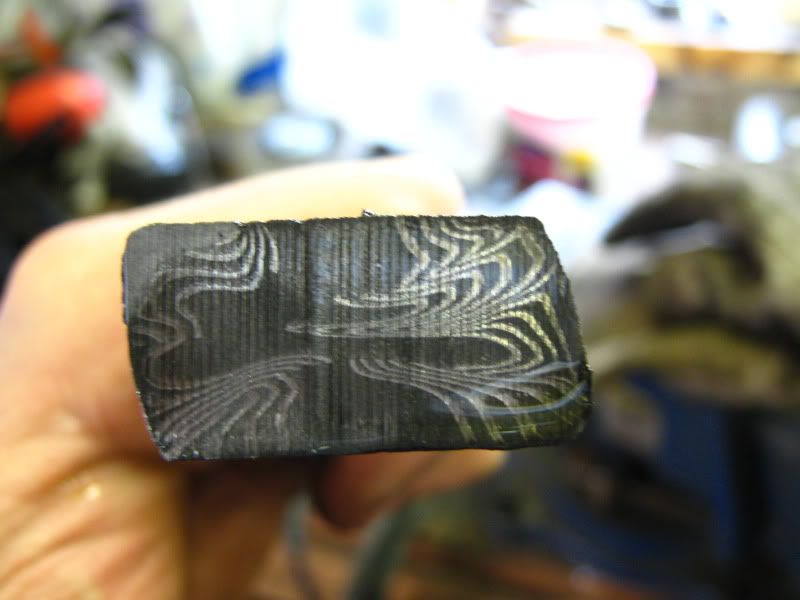

The result of that manipulation:

I'll post more later.

Thought I might come over here and share one of my projects with everyone. Hope you don't mind.

I know I've gotten a lot of great valuable information and ideas from your past WIP threads, and always look forward to seeing them, so thought I'd share one that uses some things I picked up from your threads, and maybe pass along some things and ideas to others while I'm at it.

So folks, here we go:

Technically speaking this pattern will be a mosaic, based on a modifid W pattern that was re-squared on a 45° bias, 4-wayed, and then tiled out.

This pattern starts just like it would if you were making a standard W pattern, except for varying the layer composition of the billet.

The starting billet:

18 layers of 1095 and 10 layers of 15N20. You'll notice that the middle of the billet is straight 1095, with alternating 1095/15N20 on the edges. This modification will create different thicknesses in layers and will add to the pattern development. Never underestimate what varying layer stacks/layer thickness can do for a pattern.

In for welding:

Right after the first welding press:

I grind off the mig welds to prevent billet contamination:

Forge things down into a rough square:

Next I'll use squaring dies to start squaring the billet on a 45° bias. This forces in the corners of the billet and starts distorting the layers for a sharper W effect. I picked up this from Bruce's W pattern thread.

Here's the billet after the rough trip through the squaring dies:

The billet will now be rotated 90° from its original orientation and drawn out (the "distorted" layers are now in a "vertical" orientation):

The billet drawn out and ready for a cut and restack:

The result of that manipulation:

I'll post more later.