sgmtino

Well-Known Member

Yea I only work around 3-5 hrs a day maybe longer on weekends.

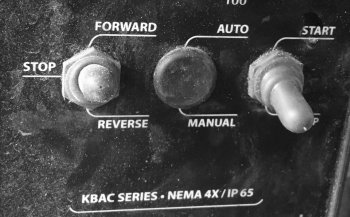

I am leaning toward this one based on cost.

I am leaning toward this one based on cost.

nothing for chinese, but these folks have good selection and excellent service https://dealerselectric.com/variable-frequency-drive-motor-control.asp

next motor to look for Boss would be an 800 rpm, with a 3" drive wheel, your sfpm at 50% is less than 400