Well, spend $80 for the cheap Chinese VFD to use while saving funds for the KBEC-27...... you might be surprised how many years it would last. https://www.ebay.com/itm/232756241295?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Thoughts on a motor

- Thread starter Daniel Macina

- Start date

Daniel Macina

Well-Known Member

Well, spend $80 for the cheap Chinese VFD to use while saving funds for the KBEC-27...... you might be surprised how many years it would last. https://www.ebay.com/itm/232756241295?

Thought about it. Just figured I would be better off getting the KB VFD. Didn't realize the cheap ones would last more then a few months even with good dust protection and ventilation.

Daniel Macina

Well-Known Member

Well, spend $80 for the cheap Chinese VFD to use while saving funds for the KBEC-27...... you might be surprised how many years it would last. https://www.ebay.com/itm/232756241295?

Dumb question but will this VFD you linked work with a 1.5 hp motor?

Dumb question but will this VFD you linked work with a 1.5 hp motor?

It's 2.2KW and rated for up to 3hp. I'm using it on a 2hp for the last few yrs. Being Chinese and knowing how they over rate in specs, I'd expect 3hp would be pushing the limit. The one I just ordered I'll be using with a 1.5hp motor. For $80 you can't go much wrong.

Daniel Macina

Well-Known Member

Thank you sir! And thank you all! You've all been very helpful to a guy that is trying his best to learn and be half as good a maker as you all are. I really do appreciate it.

Drew Riley

Well-Known Member

I have a KB vfd for my main grinder, but I've been using a chinese 2hp VFD for my mill and surface grinder for years, with no issues. Most of them are Hitachi clones, IIRC, and they're very versatile. I keep mine in a small wooden cabinet with a couple of 1/2" holes drilled in the bottom, and it's been doing just fine. If it burned up, I'd buy another tomorrow, no hesitation.

Drew Riley

Well-Known Member

When the non NEMA 4 VFDs are in close approximation to a belt grinder lots of fine metal grindings are sucked into the VFD causing it to short out . With a mill and surface grinder fluids are used to cool the tool so any grindings don't get airborne so much.

When the non NEMA 4 VFDs are in close approximation to a belt grinder lots of fine metal grindings are sucked into the VFD causing it to short out . With a mill and surface grinder fluids are used to cool the tool so any grindings don't get airborne so much.

I use very little to no coolant on my mill and SG, other than brushing a little cutting fluid on at the mill, or using a spritz or two of wd-40 from time to time. It's also on the same wall as my grinder, about 6 feet away, though it's also elevated about 5-6 feet off of the ground.

Daniel Macina

Well-Known Member

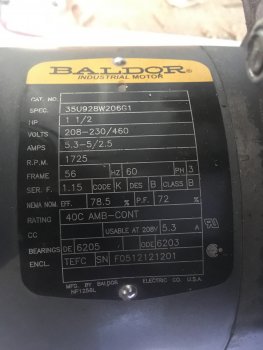

Update on the motor. It came today! Seems to be in good condition. Bearings are good no wiggle in the shaft and no signs of overheating. I made a stupid newbie mistake though. I made a list of what I needed on paper and wrote down a motor with a 56 frame (forgot to add the c.) instead of 56c like I needed. So this motor is a 56 frame. I saw the holes in the upright for face mounting but having never done this and writing down the wrong info I wasn't aware this motor wouldn't work. There are 4 holes in the base I could mount the base of the motor on but it makes the motor sit about 1/4 away from the upright. Will this work? Or could I butt the motor up against the upright and drill holes in the baseplate to make it work? Or do I need the just buy the 56c motor? In the next post I'll post pics of what I'm talking about. Sorry for the dumb questions. I feel pretty stupid right now. Lol.

Daniel Macina

Well-Known Member

Smallshop

KNIFE MAKER

Daniel...not seeing the problem? It looks like plenty of room to add holes to the base...but also looks like the existing ones will work?

If the shaft length allows you to have the pulley on properly WITH the 1/4 gap you should be fine...butting the motor to the upright add NO strength unles bolted to the face of the motor.

If the shaft length allows you to have the pulley on properly WITH the 1/4 gap you should be fine...butting the motor to the upright add NO strength unles bolted to the face of the motor.

Daniel Macina

Well-Known Member

Daniel...not seeing the problem? It looks like plenty of room to add holes to the base...but also looks like the existing ones will work?

I didn't know if it being about 1/4" away from the upright would cause problems? Didn't know if it needed to be flush with the upright.

Daniel Macina

Well-Known Member

Hi Guys.....I'm also putting together a 2x72 and looking for a motor. Where are you fellas buying the IronHorse motors from?

thanks......Jeff

This is a good spot.

https://www.automationdirect.com/

Daniel Macina

Well-Known Member

Gliden07

Well-Known Member

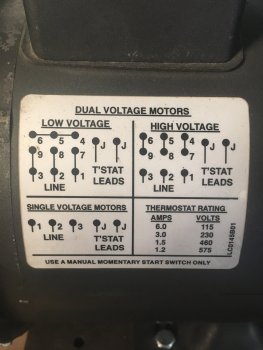

Ok guys I have a question about wiring this motor. Got everything figured out but I don't see a grounding wire. Including some pics. Do you guys see one? I don't see any green wire? I know the end of the wires look rough they came like that. I'll trim em back a bit. View attachment 63864View attachment 63865View attachment 63866

There should be a lug inside the motor for the ground there will not be a wire. All the ground will do is take your bare or Green wire and ground it to the metal case of the motor. If there is not a ground lug inside the wire compartment you should be able to attach the wire from your cord to the compartmant screws. Just get a crimp on terminal of the appropriate size.