Kevin R. Cashen

Super Moderator

Aaaand...which condition(s) are best for HT response?

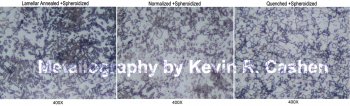

The finer the phase structures, the easier they will go into solution, and the greater the resulting hardening... unless too much is put into solution. And what may be true of one steel will not be the case with a another alloy with different chemistry. Sticking with the 10XX series, the condition that will go into solution the quickest would be that which you would get after just normalizing. For this you would want to get hot and waste no time quenching, especially with 1095. Next it would be a tie between coarse lamellar pearlite and fine spheroidal carbides- heat it up hold until heated evenly throughout and quench. Finally would be coarse spheroidal carbides. These are larger and very stable structures that will require higher temps or longer times to dissolve, a short soak at no greater than 1475°F could be in order.

For alloy steels things get much more complicated- alloying changes everything. Carbide former like Cr, will form VERY stable carbides in comparison and a very heavy spheroidal anneal is capable of what I call "carbon locking" the steel. Some of these steels are so completely annealed for free machining that they will not achieve more than a 63HRC without increasing temperatures high enough to break down those carbides. Whenever I see crazy temps being used, like 1550°F or greater for something like 80CrV2 or 52100, I know the steel is carbon locked, or being ruined in the heat treatment. The quickest and best cure for this condition is normalizing. One good heat to 1650°F followed by an air cool, and the next heat will easily give you maximum hardness.