...

@Kevin R. Cashen could give a much better/more detailed explanation

Did I hear my name?

There are three heating operations that are involved in this discussion- normalizing, and two types of annealing. I will take them in order of how soft they will make your metal. The first is normalizing, since it will do the least in softening the metal because that is not the primary goal of normalizing. Normalizing is a homogenizing operation to bring uniformity to the internal condition of the steel and, most importantly, the carbide condition. But this is regardless of the final hardness of the material, and one will find that normalizing will often result in chatter and dulled drills, mills or saw blades. Some alloy steel will even be significantly harder Rockwell after normalizing. Normalizing also involves the highest heat of these operations.

Next comes the two types of annealing. The first is lamellar annealing. This is a process of simply heating the steel high enough to put carbide into solution and then cooling very slowly to allow it to seperate out into segregated groupings within the iron matrix. We call is “lamellar” because the form the carbide will take will be sheets of alternating carbide and iron, called lamellae. This results in a phase within the steel known as pearlite, because the alternating bands in the lamellae scatter the light of a metallographic to make it look like mother of pearl. This is the most common phase that you will get whenever you are heating or cooling steel, as it is the natural form that the carbide will want to take when coming out of solution. Since this phase results in sheets, or lamellae, it will also chatter drills and give resistance to cutting when the cutter encounters these carbide sheets between the soft iron. With steels above .83% carbon there will be even greater degrees of carbide segregation and in more undesirable forms. One should never lamellar anneal any steel that has carbide volumes above the eutectoid, or above .83% as will not only trash your tools it will be very detrimental to the steel itself.

The last, and most thorough, method of annealing is spheroidizing, or spheroidal annealing. It gets its name from the resulting form the carbide takes, which is balled up into little spheroids scattered uniformly throughout the iron matrix. Spheroidizing is so thorough and affective because it does not put the carbide into solution with its heating temperature. To do this properly you will always stay below the temperature at which the carbide will go into solution, avoiding the sheeting effects of pearlite. Think of it like this- drop a bunch of wax shavings or solder on a metal plate and begin to heat it. As the wax/solder begins to melt the first thing it will do is ball up, only after you really heat the plate will the wax/solder then spread out in a sheeting action over the surface.

I have described the difference in cutting material in the two conditions like this- imagine that you have to shovel a pile of metal pieces, one pile is in the form of various sized plates, the other is in the form of a pile of ball bearings- which will be the easiest to plunge the shovel into? This is exactly why spheroidizing works so well, and why it is indeed the most thorough and complete form of annealing if you wish to soften the metal, and that is the reason that steel mills supply the industry with spheroidal annealed material. If you have steel that is hard to cut as received it will often be cold rolled. Cold rolled material may come annealed or it may be as is, in which case it will be a bit springy as it will obviously be work hardened. This is often the case with 15n20. Unless it is precision ground, the really clean looking stuff will be cold rolled and not annealed. The matt silver or clean light gray looking stuff will be CRA (cold rolled annealed). The dark gray stuff with rounded edges is hot rolled, and will generally be a bit softer in carbon steel.

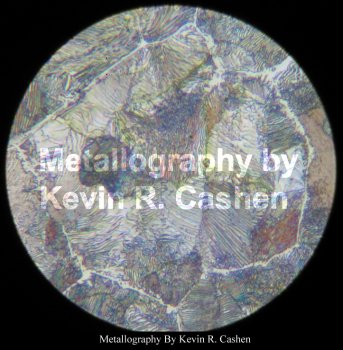

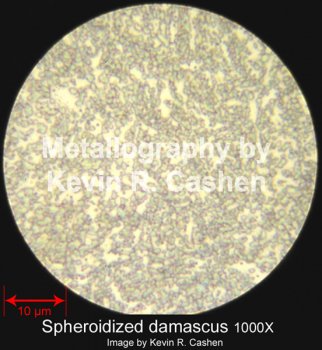

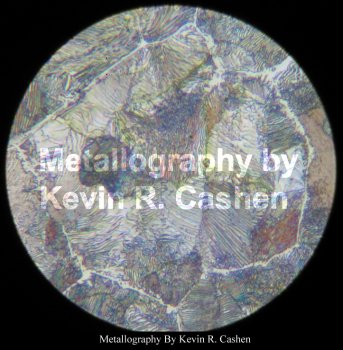

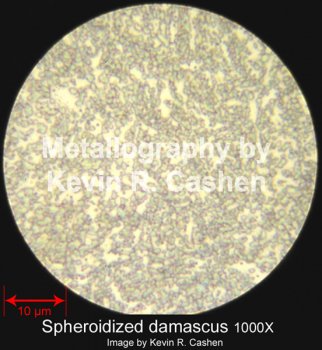

Here are micrographs to clearly show the difference between lamellar and spheroidal annealing:

The lamellar has the layered condition of pearlite as well as proeutectoid carbide networking in the grain boundaries, indicating that it is 1095, and this condition is bad for your tools and bad for the steel itself.

The spheroidized material, on the other hand is very uniform, and will easily be the softer of the two. If I have to mill a piece of steel, I will definitely spheroidize it. If I make Damascus for others, I will always do a complete industrial spheroidal anneal on it so that the customer can easily cut it.