I think a lot of people over think and over build stamp presses. I use just a straight up, simple, unaltered arbor press from harbor freight. There is no need to modify it at all. Then you can still use it for other things. This is the setup that I use.

The whole process takes about 1 minute or less.

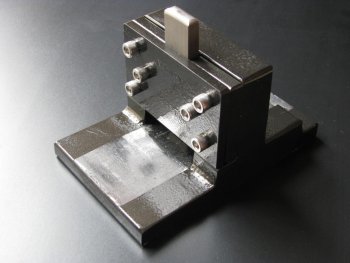

Here's a picture of the press. It costs about $30 I think. It's bolted to the bench and there is a piece of 1/4" mild steel plate just setting on the base of the press.

Here's the blade set on the base ready to place my stamp. It has a layer of masking tape to protect the ricasso from scratches on both sides. The tape also helps keep the stamp from slipping.

Now I have positioned my stamp where I want it and bring the press arm forward so the weight of the ram holds the stamp in place. I check quick to make sure the stamp is straight up and down front to back and side to side.

Lastly I take the press arm handle and apply some pressure to the stamp so nothing moves or bounces then I give the ram a good rap with the hammer to ensure a good deep stamp. And done. No bouncing, no double stamp and no hassle.

This is just how I do it. I'm only trying to demonstrate that you can stamp without buying that expensive holder or doing a lot of work to modify an existing press.

My stamps come out exactly where I want them on the blade and perfect everytime. I stamp my blades cold but they are annealed and dead soft when I do it. Thermal cycling always follows stamping.