Mason Knives

Well-Known Member

Hi All, joined today, great forum!

Thought i post a recent knife i made. I have been making knives for a short time, this is my 26th attempt.

All comments, good or bad greatly appreciated!

Many thanks

Paul.

Sway

back Jack

RWL-34 Blade and spring

Black paper micarta scales

Stainless hardware

Blade length 3 1/8"

www.masonknives.co.uk

Thought i post a recent knife i made. I have been making knives for a short time, this is my 26th attempt.

All comments, good or bad greatly appreciated!

Many thanks

Paul.

Sway

back Jack

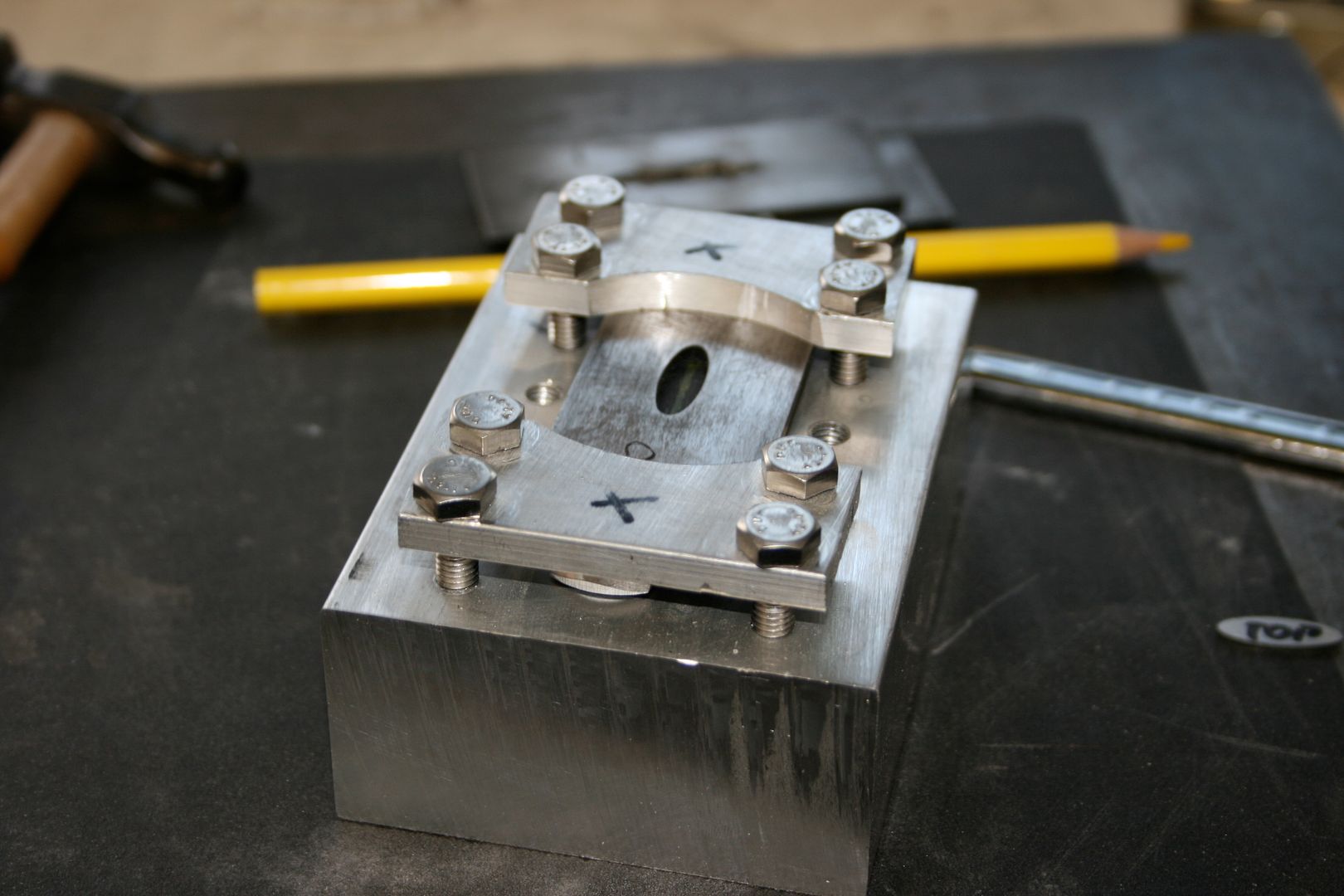

RWL-34 Blade and spring

Black paper micarta scales

Stainless hardware

Blade length 3 1/8"

www.masonknives.co.uk