MTBob

Well-Known Member

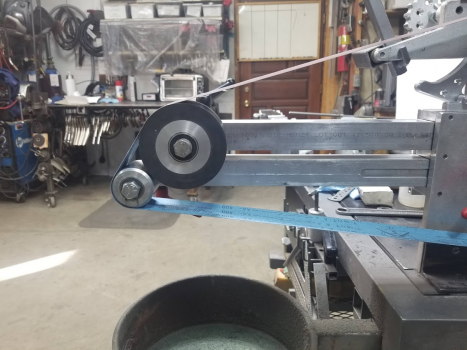

My wife is beginning to believe that I'm not making knives, just shopping for new tools. Well, that issue came up again while I was considering buying a rotary platen attachment for the 2x72. I see the purpose and have read a bunch of reviews that confirm their usefulness. So, this afternoon I began fiddling with various ways of using the stuff I've got to work around buying a new 'thing".

Here's what I came up with. I did a couple of test grinds and it seems to do the trick. It allows me to vary the firmness of the belt simply by positioning the upper wheel farther from the lower wheel. This results in an infinitely variable tension between the wheels, as opposed to the fixed wheels of a rotary platen. The belt tension between wheels certainly isn't a firm as a rotary platen that uses a secondary belt behind the primary belt.

Though I haven't tried it yet, I anxious to see how this setup works on contouring handles using a 1" scalloped belt.

So, for those of you who have a rotary platen, does it seem this setup would be adequate to replace a rotary platen? What's the downside?

Here's what I came up with. I did a couple of test grinds and it seems to do the trick. It allows me to vary the firmness of the belt simply by positioning the upper wheel farther from the lower wheel. This results in an infinitely variable tension between the wheels, as opposed to the fixed wheels of a rotary platen. The belt tension between wheels certainly isn't a firm as a rotary platen that uses a secondary belt behind the primary belt.

Though I haven't tried it yet, I anxious to see how this setup works on contouring handles using a 1" scalloped belt.

So, for those of you who have a rotary platen, does it seem this setup would be adequate to replace a rotary platen? What's the downside?