You'll get there Ctone.

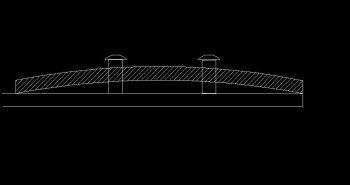

It isn't the end of the world. Over time we all devise steps or methods that allow us to back track problems as they arise instead of attacking everything willy-nilly when it's too late to fix just that one thing. If you're going to keep flatening with your platen, make sure it's kicked out a speck past the two wheels. This will help keep your belts flater to the platen, assuming the platen is flat too, but still isn't the ultimate solution. Keep at it.

Rudy

It isn't the end of the world. Over time we all devise steps or methods that allow us to back track problems as they arise instead of attacking everything willy-nilly when it's too late to fix just that one thing. If you're going to keep flatening with your platen, make sure it's kicked out a speck past the two wheels. This will help keep your belts flater to the platen, assuming the platen is flat too, but still isn't the ultimate solution. Keep at it.

Rudy