Nick Riggi

Well-Known Member

I was wondering what method everyone uses when cutting wood blocks/stock down to usable scale sizes. I dont have a table saw with fence ( that would be the optimal setup)

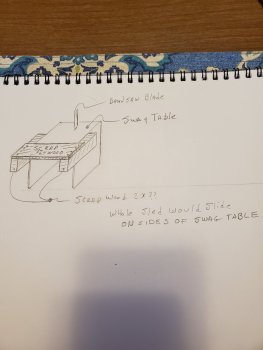

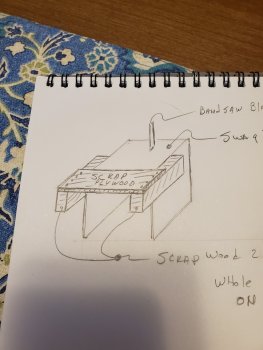

I have been using my Portaband that is in a Swag table. I mark out the block to the desired size then steadily try to keep on the line- is ok but never seems to work perfect.

The table dosent really have room to clamp things down as the sides are all rounded off.

Any suggestions or tricks to help?

I have been using my Portaband that is in a Swag table. I mark out the block to the desired size then steadily try to keep on the line- is ok but never seems to work perfect.

The table dosent really have room to clamp things down as the sides are all rounded off.

Any suggestions or tricks to help?