Abbott

Well-Known Member

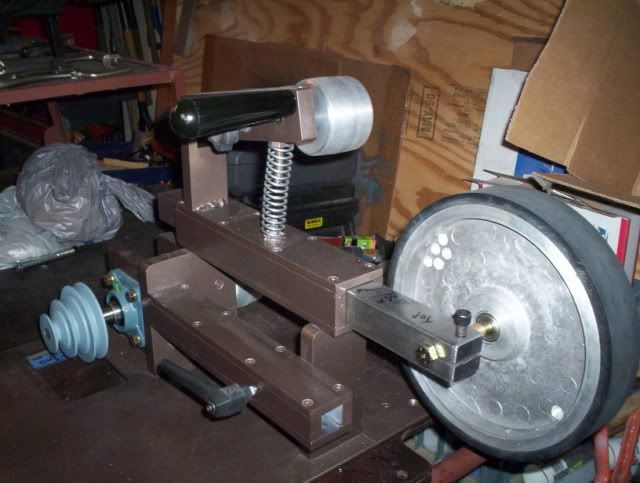

I am working up a new belt grinder and I always enjoy seeing photos of other's work so here is one of mine:

I am running a 3hp Harbor Freight motor, 220v 1ph with a 4 step pulley. I have another work rest that is about half the size of the one in the photo and is made of 1/4" steel plate. I also have a 10" wheel arm for it. I have yet to build a work arm with a small wheel attachment but I have all of the parts to do so, I just need the time to get it and the wheels built. Heh, it looks like one of my my dogs photo bombed me ! That's Boko, he recently turned 4 years of age.

That's Boko, he recently turned 4 years of age.

I am running a 3hp Harbor Freight motor, 220v 1ph with a 4 step pulley. I have another work rest that is about half the size of the one in the photo and is made of 1/4" steel plate. I also have a 10" wheel arm for it. I have yet to build a work arm with a small wheel attachment but I have all of the parts to do so, I just need the time to get it and the wheels built. Heh, it looks like one of my my dogs photo bombed me !

Last edited: