Austin Thrasher

Well-Known Member

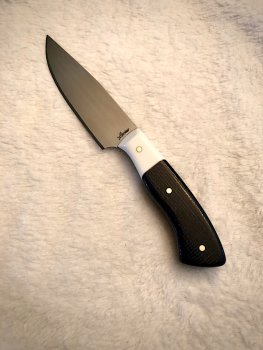

Hey guys, I just got an order from a repeat customer for a set of 8 matching steak knives for his brothers birthday. I’ve never even thought about steak knives design wise and would love to hear what y’all thought. I want to use stainless but am not sure what to go with. I have an Evenheat oven so I can do more precise ht. I also have air and aluminum quench plates. Here is a list of questions:

What steel? If I go with AEBL, can I get away with no cryo or should I make the leap to get that equipment? I’ve never done dry ice and don’t know how yet or even if it gets cold enough to justify the effort. Alpha says it need to get to -95.

What thickness for a steak knife?

I’m thinking the width on what I design should be around an inch or so. Is that too wide or should I go with something a little slimmer? It will probably be around 8” total. 3.5 or 4” cutting edge.

Plungeless or plunge with Spanish notch?

I like jimping with a checkering file. Yay or nay? I guess food could potentially be caught in the jimping and cause bacterial issues possibly. It does look nice though.

He wants walnut handles. I love tru oil on walnut. Is that “food grade enough” for a kitchen cutlery application or should I go with something else?

Thanks in advance guys. I know some of these questions are gonna be simply dependent on my own personal style (as it should be since I’m the maker on these blades lol) but would greatly appreciate hearing your thoughts, tips, or opinions on what you would do. Thanks again!

What steel? If I go with AEBL, can I get away with no cryo or should I make the leap to get that equipment? I’ve never done dry ice and don’t know how yet or even if it gets cold enough to justify the effort. Alpha says it need to get to -95.

What thickness for a steak knife?

I’m thinking the width on what I design should be around an inch or so. Is that too wide or should I go with something a little slimmer? It will probably be around 8” total. 3.5 or 4” cutting edge.

Plungeless or plunge with Spanish notch?

I like jimping with a checkering file. Yay or nay? I guess food could potentially be caught in the jimping and cause bacterial issues possibly. It does look nice though.

He wants walnut handles. I love tru oil on walnut. Is that “food grade enough” for a kitchen cutlery application or should I go with something else?

Thanks in advance guys. I know some of these questions are gonna be simply dependent on my own personal style (as it should be since I’m the maker on these blades lol) but would greatly appreciate hearing your thoughts, tips, or opinions on what you would do. Thanks again!