Brad Lilly

Moderator and Awards Boss

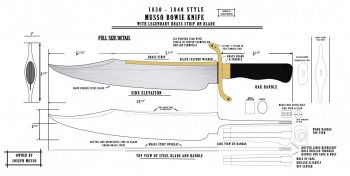

I got a request for a big stainless bowie knife (11" plus blade). What do you guys recommend for something like this? I was going to use 440c just because of its high corrosion resistance but I'm not sure ho its going to hold up on that big of a blade.

I'm not sure I like the idea of making a knife without forging, it just dose not seam natural to me.

I'm not sure I like the idea of making a knife without forging, it just dose not seam natural to me.