opaul

Well-Known Member

I've made a couple of these knives and can share in my experience. Compressed leather makes the best type leather to use for making stacked leather handles. Compressed leather is the best, whether you compress it inhouse or buy it alreaday compressed. I did a few knife handles where I soaked the leather washers ( size depends on the knife you are making) in water and then used shop clamps to compress and then dry. Buying the leather already compressed is the way to go in my opinion.

Leather washers have to be sanded with a slow speed and a sharp belt. It doesn't hurt the leather to dip it in water or use your finger to apply water to the leather as you are sanding it. Uncompressed leather tends to be fuzzy and doesn't sand well. Whereas compressed leather is the opposite.

I like to use a slack belt and also scalloped belts for the finished shaping and shaping, especially where the handle is contoured, and then its hand sanding to whatever grit you decide works for you. Finish can be wax but this tends to dull quickly or you can use boiled linseed oil or gunstock tru-oil. Really not much different than finishing wood stocks.

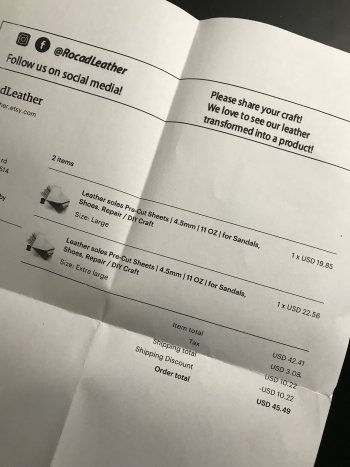

I like using sole leather in 11oz. It seems to the the right thickness and looks and finishes well. I purchased my most recent leather soles from Rocadleather. They come in precut sheets used for making sandles and shoe repair.

I hope this helps. Like I said it works for me, you may like another method.

Leather washers have to be sanded with a slow speed and a sharp belt. It doesn't hurt the leather to dip it in water or use your finger to apply water to the leather as you are sanding it. Uncompressed leather tends to be fuzzy and doesn't sand well. Whereas compressed leather is the opposite.

I like to use a slack belt and also scalloped belts for the finished shaping and shaping, especially where the handle is contoured, and then its hand sanding to whatever grit you decide works for you. Finish can be wax but this tends to dull quickly or you can use boiled linseed oil or gunstock tru-oil. Really not much different than finishing wood stocks.

I like using sole leather in 11oz. It seems to the the right thickness and looks and finishes well. I purchased my most recent leather soles from Rocadleather. They come in precut sheets used for making sandles and shoe repair.

I hope this helps. Like I said it works for me, you may like another method.