..

a few more results from this morning..

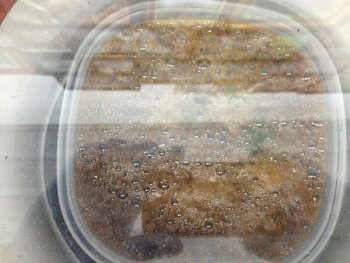

first, this is stag that was soaked in Fiebings dark brown oil based leather dye using vacuum and soaking for a week.

The bone (cut piece lower right) and stag (cut piece lower left) took dye all the way through but it is not a color I would call attractive. It came out more purple than brown. Maybe several weeks would darken the color to brown. I am going to put some in a jar and set it to the side for a month and check. I'd call the deep dye with this a bust.....but the exterior of the stag OMG...I pulled the pieces out and let them dry. After cutting the bone and being disappointed, I started looking at the stag.

It had such a great color I went and buffed the stag up. The color is fantastic. It has just the right reddish brown that makes a stag amazing. These rounds and tapers I grabbed at random from my stock. They were fairly dull but after they dye and a little buffing BAM!

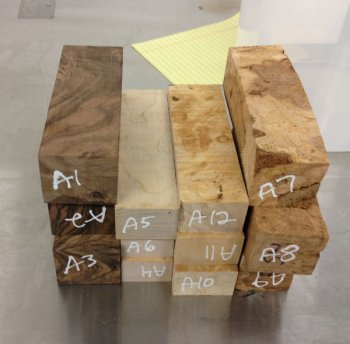

Here I have three pieces I pulled out from maple brown dyed Ultraseal. They are Walnut, birdseye maple and maple burl. I soaked these under vacuum for 24 hours. I am trying different types of wood to see how long I need to keep them in the juice to get good dye penetration. The maple dye really looks nice here. The center piece picked up some chatoyance (3D look of wood when you rotate it in the light -- you can see into the wood and see the grain in 3D) in the soak. These are in the oven right now.

The stag I had in Ballistol in the mini crock pot cooked for 4 hours or so. I cut and ground some this morning to see how it penetrated. It didn't penetrate worth a flip. I really thought the heat would cook the dye in quicker. Nope. I opened the pot and caught a strong whiff of Ballistol fumes. Not good. I opened the big roll up door and hit the exhaust fans to clear out the fumes.

Maybe it needs heat a lot longer. I am not going to pursue that right now. I will throw this in a jar and let it get a few vacuum cycles and then it can sit and soak for several weeks.

So far...

The 2 MMA's I have tried so far (two more in the oven right now) seem to work well. Weight on soft wood nearly doubled after soaking in a vacuum for a day and then heat cured. It all smells really bad. It's flammable, explosive and toxic. Still, this is with in reach of the average knife maker if you want to invest in the equipment and you work safely. I did not use any pressure, only vacuum.

Dyeing wood is more interesting. I had good success with using aniline dye in both powder and liquid. Liquid is easier to use. Soaking in denatured alcohol, under vacuum for a week gave a complete, very deep dye to (softer) wood. I have yet to test on dense, hard wood like rock maple. I expect that is just a matter of trial and error to get the time down.

Double dyeing is even more interesting. A dye session in one dyed batch of MMA, harden and then a longer soak/vacuum in another color and harden. Getting the results to repeat is going to be a challenge give how different wood is from piece to piece. Still, it's a matter of trial and error here it seems at this point.

Deep dyeing bone or stag continues to be a challenge. I was hoping for faster turnaround time. It's not going to happen. I am going to have to lengthen soak/vacuum times considerably.

Leather dye works well on the outside of stag and bone but beauty is only skin deep (ha!). Dark Brown Oil based leather dye gave the stag some exceptional mojo. Will it wear off? Yep, just like the potassium permanganate coloring wood but a soaking under vacuum for a week is going to get the dye slightly deeper than just the surface so it should wear for a long time.