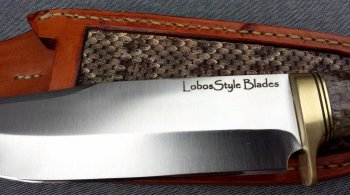

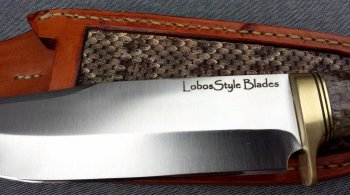

LobosStyle Blades

Well-Known Member

So about a year ago I was asked if I could make a knife with a snake skin handle. Being a new maker I had NO CLUE what I was getting into. I said, "I've never done one before but I can sure try." Today I finally handed it off to the customer in which his first comment was "Wow! It's so nice I'm afraid to use it. I might have to put it up for display." This hit home for me because my entire goal in making knives is to make something someone will be "Proud to Carry".

This piece took over a year to accomplish with months on months of trial and error..... oh SOOOOO MANY failed attempts to get it right. The hardest part was getting the protective coating that wouldn't separate from the skin causing a fogged/frosted look but also I could work and polish and be durable for actual use.

In addition, I've never made a sheath with an inlay window let alone have that inlay be snakeskin.

I hope you all enjoy and please feel free to make comments and suggestions.

Blade: 6inches - 3/16" thick 440c stainless 58-59hrc

Guard/Pommel: Brass with black spacers

Handle: Rattlesnake skin

This piece took over a year to accomplish with months on months of trial and error..... oh SOOOOO MANY failed attempts to get it right. The hardest part was getting the protective coating that wouldn't separate from the skin causing a fogged/frosted look but also I could work and polish and be durable for actual use.

In addition, I've never made a sheath with an inlay window let alone have that inlay be snakeskin.

I hope you all enjoy and please feel free to make comments and suggestions.

Blade: 6inches - 3/16" thick 440c stainless 58-59hrc

Guard/Pommel: Brass with black spacers

Handle: Rattlesnake skin

Last edited: