Mark Barone

Well-Known Member

This I believe is only my seventh knife, since I started this hobby over 2.5 years ago. I’m banging them out.

6 inch OAL

3/16 wide

1095 steel

Purple Heart scales (1000 grit, Tung Oil )

Red spacers

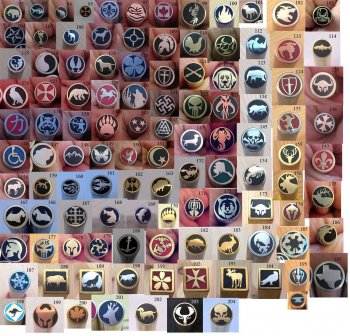

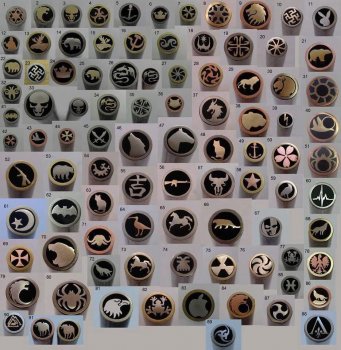

3/8 mosaic pin

1/4 inch lanyard pin

Acid Finish 50:50 acid and cider vinegar 30 minutes

Please feel free to critique so I can progress. Some things I would have preferred to do but played it safe.

I wanted the bevel a little wider. The acid finish is also not as consistent as I would have like it. This was my first try. It’s just an acid etch, I haven’t purchased a tumbler or vibrator yet.

6 inch OAL

3/16 wide

1095 steel

Purple Heart scales (1000 grit, Tung Oil )

Red spacers

3/8 mosaic pin

1/4 inch lanyard pin

Acid Finish 50:50 acid and cider vinegar 30 minutes

Please feel free to critique so I can progress. Some things I would have preferred to do but played it safe.

I wanted the bevel a little wider. The acid finish is also not as consistent as I would have like it. This was my first try. It’s just an acid etch, I haven’t purchased a tumbler or vibrator yet.