Smurf masher

Well-Known Member

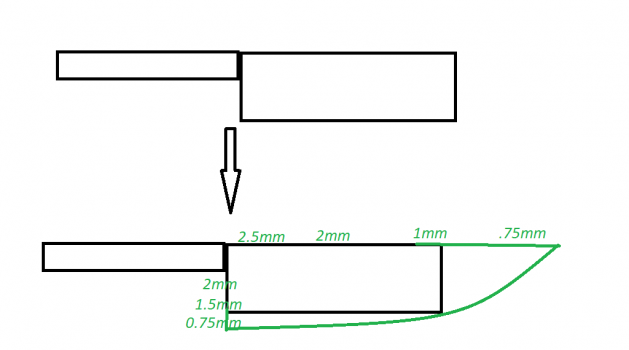

I've bought a load of it. And it's 2.5mm thick. I think I could easily cut to chape with a saw, and then stock remove to get the right shape.

But... part of me wants to cut to the shape below then extend out the blade with a hammer and forge, bulk up the bolster, and shape the blade curve. That's my artistic side... my scientific side is screaming that this steel is created layer by layer to get the perfect grain, and heating it up and wacking it may revert this super steel to something less "super"

Or... would forging around the blade edge actually work harden it and make it even tougher? I'm airing towards just stock removal for these kitchen knives. Bu I do want to add some blacksmithing if I can to add the taper and the shape if I can without destroying the steel, and also so I can reduce waste as this steel is expensive.

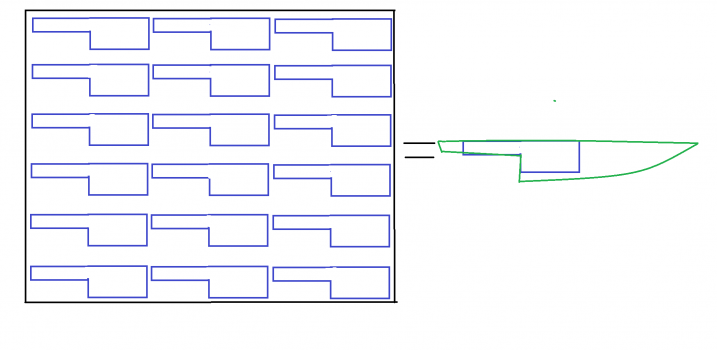

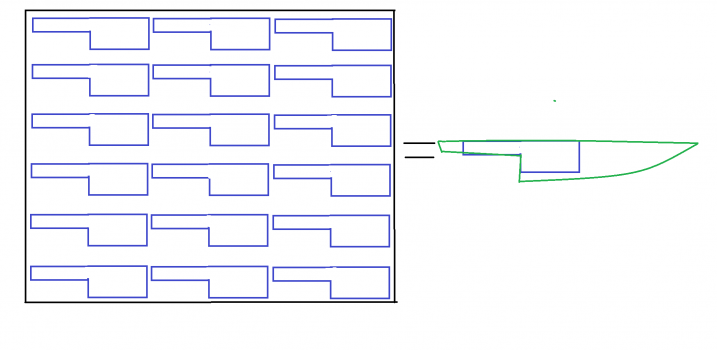

If I can cut to these shapes I could basically avoid any wastage.

But... part of me wants to cut to the shape below then extend out the blade with a hammer and forge, bulk up the bolster, and shape the blade curve. That's my artistic side... my scientific side is screaming that this steel is created layer by layer to get the perfect grain, and heating it up and wacking it may revert this super steel to something less "super"

Or... would forging around the blade edge actually work harden it and make it even tougher? I'm airing towards just stock removal for these kitchen knives. Bu I do want to add some blacksmithing if I can to add the taper and the shape if I can without destroying the steel, and also so I can reduce waste as this steel is expensive.

If I can cut to these shapes I could basically avoid any wastage.