CreativeMan.com.au

Member

thought I could share some photos of putting handles on a blade I made last year.

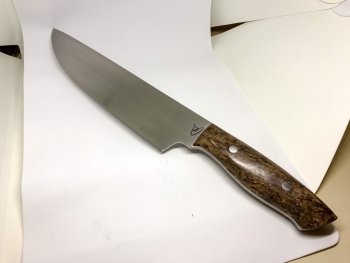

The blade is this chef blade I keep making in slightly different versions, I call it the "ScandiChef".

If nothing else I am Scandinavian and it is a chef blade

The blade is in 12C27, stock removal, heat treated by quenching in canola oil from 1080 C and tempering 2 x 2 hours at 200 C. Estimated 56 HRC after having similar blades hardness tested after this heat treat recipe before.

Handle scales are flattened on the inside by sanding on a piece of glass with coarse sand paper on it. Then drilling holes for the 1/4" steel pins. I clamp and pin the scales to each other first and shape the front to final shape, as well as sand to final grit. This is easier to do on the front now, than after when the blade is between the scales. The photo below is before they were clamped and the front shaped, a dry-fit to make sure the holes line up

The blade is this chef blade I keep making in slightly different versions, I call it the "ScandiChef".

If nothing else I am Scandinavian and it is a chef blade

The blade is in 12C27, stock removal, heat treated by quenching in canola oil from 1080 C and tempering 2 x 2 hours at 200 C. Estimated 56 HRC after having similar blades hardness tested after this heat treat recipe before.

Handle scales are flattened on the inside by sanding on a piece of glass with coarse sand paper on it. Then drilling holes for the 1/4" steel pins. I clamp and pin the scales to each other first and shape the front to final shape, as well as sand to final grit. This is easier to do on the front now, than after when the blade is between the scales. The photo below is before they were clamped and the front shaped, a dry-fit to make sure the holes line up