You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

question re: HT

- Thread starter Bruce McLeish

- Start date

Canesplitter

Member

Bjmac!

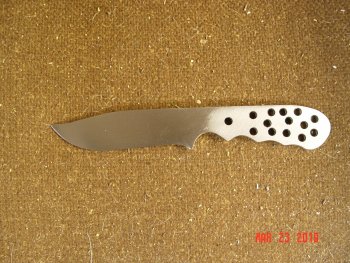

I hope, you don´t mind, that I altered your immage a bit.

I thought that knife needs a different clippoint. You should try to get a crisper transition from the blade to the ricasso.

Just my two cents.

And yes by all means, finish this knife.

Good success!

Cheers

Canesplitter

I hope, you don´t mind, that I altered your immage a bit.

I thought that knife needs a different clippoint. You should try to get a crisper transition from the blade to the ricasso.

Just my two cents.

And yes by all means, finish this knife.

Good success!

Cheers

Canesplitter

J. Hoffman

Dealer - Purveyor

I think it looks great for a first knife. The recommendations Canesplitter gave are spot on. I would also recommend against finger grooves unless the knife is for a specific person. What may fit your hand perfectly may be uncomfortable for someone else.

EdCaffreyMS

"The Montana Bladesmith"

I can't see the thickness from the pics, but that is one of the aspects I feel is very important. Most newer knifemakers believe they should have things as close to finished dimensions as possible.... not always a good thing pre-heat treat. I generally recommend leaving the blade's edge about the thickness of a nickel. Heat treat, and finish grind post heat treat......

NOW.....that's assuming there is a belt grinder involved. If it's all by files/hand, then you have no choice other than to get things very close to finished dimensions pre-heat treat.....otherwise you likely have no way to finish it, beings that a file will not cut it post heat treat.

Everything else looks like it's ready for heat treat. Finish on any blade should be at least 120 grit prior to heat treat. (any scratches left in the blade larger than 120 grit has a strong potential to creak stress risers (places that will crack when hardened/quenched.

NOW.....that's assuming there is a belt grinder involved. If it's all by files/hand, then you have no choice other than to get things very close to finished dimensions pre-heat treat.....otherwise you likely have no way to finish it, beings that a file will not cut it post heat treat.

Everything else looks like it's ready for heat treat. Finish on any blade should be at least 120 grit prior to heat treat. (any scratches left in the blade larger than 120 grit has a strong potential to creak stress risers (places that will crack when hardened/quenched.

Bruce McLeish

Well-Known Member

Thank you for the responses , guys. Canesplitter, I like your design better than mine.! That's the one for the next attempt.

BTW, I really like the way you altered the photos.

J Hoffman , Thanks for the reply, Your advice on the finger groves is spot on. However, in this case the knife is for a specific guy (who also has giant fingers... The blade shape is also his design.)

Ed Caffrey, I respect your opinion very much...as the blade is all hand/files/handsanding, I guess that I have to go much closer to finished dimensions. The steel is 3/16" 1084. the blade edge at this point is .080" and the finish is 180 grit sanded in 2 directions - one "cross grain" the final one length ways. So, I'm taking that I should file the edge closer to sharp, and the finish closer to, well, finish?

Thanks again for the responses, as you can tell, I need all the help I can get!

BTW, I really like the way you altered the photos.

J Hoffman , Thanks for the reply, Your advice on the finger groves is spot on. However, in this case the knife is for a specific guy (who also has giant fingers... The blade shape is also his design.)

Ed Caffrey, I respect your opinion very much...as the blade is all hand/files/handsanding, I guess that I have to go much closer to finished dimensions. The steel is 3/16" 1084. the blade edge at this point is .080" and the finish is 180 grit sanded in 2 directions - one "cross grain" the final one length ways. So, I'm taking that I should file the edge closer to sharp, and the finish closer to, well, finish?

Thanks again for the responses, as you can tell, I need all the help I can get!