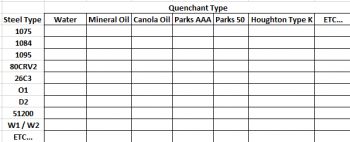

Here is an excerpt from an article I am working on for the ABS. The article will have a full listing of quench oils and steels I have worked with or tested, but I reserve that level of thoroughness for platforms where I can get due credit for the research hours spent in compiling the data. My input is the result of 40 years of hard work in all aspects of bladesmithing and I have found that forums are a good place to quickly have your name stripped from your work on the retelling.

Most oils will come in two categories- fast (7-10 seconds in the nickel ball test), and medium speed (11-14 seconds in the nickel ball test). There may be new numbers generated by other tests, such as the GM Quenchometer, but the nickel ball has been around a long time.

Fast (7-10 seconds): Parks #50 (7-9 seconds), Houghto-Quench “K” (7-9 seconds),

Medium (10-14 Seconds): Parks AAA (9-11 seconds), Houghton Bioquench 700 (10.2 seconds), Houghto-Quench “G” (11.5 Seconds)

I have no set range for Canola oil since it is quench oil alternative and not an actual quenchant, for a range of numbers I would refer you to the work of George Totten who found canola to be a fast quenchant but with unstable and inconsistent properties in its raw form. Totten thus suggested canola as a possible base for a formulated quenchant.

I have no set numbers on “mineral oil” as it is not a quenchant, but rather simply a label applied to any number of oils that are non-organic. The only measurable quality would be viscosity for the given “mineral oil” you are working with.

Water is, of course, the fastest of the quenchants mentioned but actually too fast for most blades shapes and the problems with distortion and cracking are what made oil based quenchants necessary.

Steels requiring a fast quenchant (7-10 seconds): 1070, 1075, 1080, 1084, 1095, W-1, W-2, 26C3, 15n20

Steels requiring medium quenchant (10-14 seconds): 80CrV2, 52100, 5160, O-1, L-6

*There is a range of Citgo oils but the 510 is the fastest and the only one I would bother with for knives.

note- Many numbers are cross referenced from the obsolete ASTM 3520 (Quenchometer) so are approximates or ranges.