Contender Machine

Dealer - Purveyor

I first introduced these quench plate presses at BladeShow Atlanta this year and they were extremely popular. I am finally at a point where I have a decent supply in stock so I thought I would offer them up to the KnifeDogs crowd.

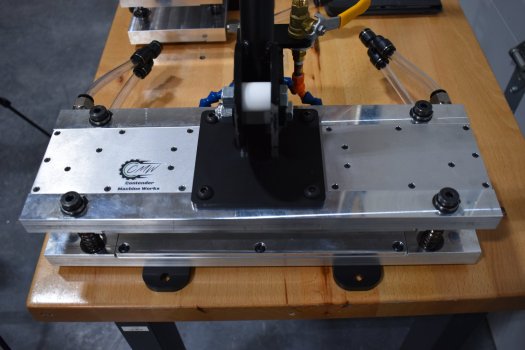

I believe these are the first commercially available quench plates that are both water and air cooled, water pumps through the plates and air blasts in between the plates. Also these are different because instead of a vise/clamping action they are a cam over press action. This offers two huge benefits, speed and pressure. With this design a blade can be under a 1000+ psi clamp in as little as one second from being removed from the heat.

To test the prototype of this I prepared 80 identical full tang, 3 inch blade blanks in M390, 1975 degrees. I heated them all in 6 blade batches. The first 40 I quenched with plain, fully machined aluminum plates. These plates warmed up with each consecutive quench and by the 6th blade were getting quite hot. This of course meant a deviation in the quench speed. Also due to the nature of two separate plates there was potential rocking and not nearly as much pressure.

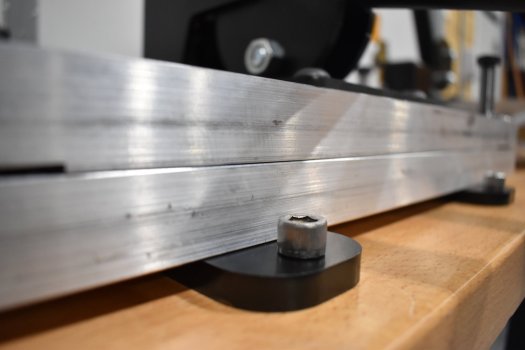

The second half of the blades I ran through the quench plate press. After each blade was quenched I could put my hand on the inside of the plates and they were cool to the touch. The quick action and mechanical advantage meant that I could have a blade clamped under 1000+ psi of pressure very quickly. The movable plate is guided by 4 heavy duty linear bearings on ground guide rods so it is very smooth with no rocking. This all meant a much more consistent quench between the blades and the best part is that it almost completely eliminated any warping! This in itself if well worth the investment.

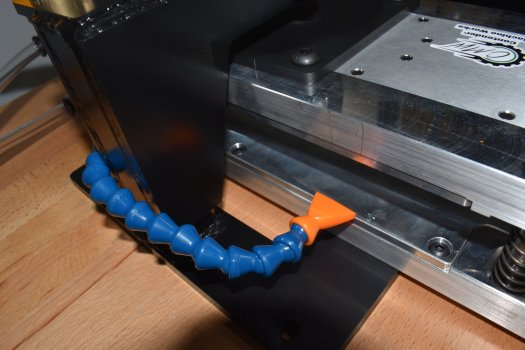

The air dump in between the blades is done with a ball valve so it can be opened quickly right after the blade is clamped. Then it can be easily shut off right before unclamping. I just ran full shop pressure of 145 psi. Though anything less than that will still help for sure.

The plates I had at BladeShow were 15.5 inches long and 6 inches wide. I had a lot of requests for longer plates so now I am making them 18 inches long. I also made a new variation that has replaceable sub plates so if they get wore out or damaged they can be replaced easily and cheaply.

Specs:

Dual water cooled plates with an air blast between the plates.

1x6x18 inch fully machined aluminum plates.

Heavy steel frame and handle.

4 Bolt holes for easy mounting to a bench.

Mounted ball valve and air lines.

8 Feet of inlet and return water line included.

The sub plate variation includes one set of plates installed. Replacements are available.

Pictures below.

I have these available on my website or feel free to reach out to place an order.

www.contenderworks.com

www.contenderworks.com

Feel free to ask any questions below!

Thank you,

Darren

I believe these are the first commercially available quench plates that are both water and air cooled, water pumps through the plates and air blasts in between the plates. Also these are different because instead of a vise/clamping action they are a cam over press action. This offers two huge benefits, speed and pressure. With this design a blade can be under a 1000+ psi clamp in as little as one second from being removed from the heat.

To test the prototype of this I prepared 80 identical full tang, 3 inch blade blanks in M390, 1975 degrees. I heated them all in 6 blade batches. The first 40 I quenched with plain, fully machined aluminum plates. These plates warmed up with each consecutive quench and by the 6th blade were getting quite hot. This of course meant a deviation in the quench speed. Also due to the nature of two separate plates there was potential rocking and not nearly as much pressure.

The second half of the blades I ran through the quench plate press. After each blade was quenched I could put my hand on the inside of the plates and they were cool to the touch. The quick action and mechanical advantage meant that I could have a blade clamped under 1000+ psi of pressure very quickly. The movable plate is guided by 4 heavy duty linear bearings on ground guide rods so it is very smooth with no rocking. This all meant a much more consistent quench between the blades and the best part is that it almost completely eliminated any warping! This in itself if well worth the investment.

The air dump in between the blades is done with a ball valve so it can be opened quickly right after the blade is clamped. Then it can be easily shut off right before unclamping. I just ran full shop pressure of 145 psi. Though anything less than that will still help for sure.

The plates I had at BladeShow were 15.5 inches long and 6 inches wide. I had a lot of requests for longer plates so now I am making them 18 inches long. I also made a new variation that has replaceable sub plates so if they get wore out or damaged they can be replaced easily and cheaply.

Specs:

Dual water cooled plates with an air blast between the plates.

1x6x18 inch fully machined aluminum plates.

Heavy steel frame and handle.

4 Bolt holes for easy mounting to a bench.

Mounted ball valve and air lines.

8 Feet of inlet and return water line included.

The sub plate variation includes one set of plates installed. Replacements are available.

Pictures below.

I have these available on my website or feel free to reach out to place an order.

Quench Plate Press — Contender Machine Works

The Contender Machine Works quench plate press is the easy solution for heat treating your air hardening steels. The press features machined 1 inch thick aluminum plates that ride on linear bearings for a smooth and accurate plate quench. Both 15.5- and 18-inch-long plates available. Please inquire

Feel free to ask any questions below!

Thank you,

Darren